Laser cutting of pipes, profiles and beams

Pipes, profiles and beams are available in various dimensions, materials and designs and are used in a wide range of industries, such as the automotive and construction sectors. Cutting a wide variety of material geometries using fiber lasers is a modern and extremely efficient processing method.

Laser cutting of profiles

Profiles have an elongated structure in various cross-sectional shapes such as U, L, T or I and are often made of metal such as steel, stainless steel or aluminum. Profiles are used in many sectors, such as mechanical engineering, vehicle construction and the furniture industry, and come in different shapes and sizes depending on the requirements. The conventional processing of profiles used to require several downstream work steps such as sawing, punching and drilling the components. With modern laser cutting of profiles, these individual steps can be combined into a single work process, saving processing time and costs.

Laser cutting of beams

Beams are a special type of profile that are characterized by strength and stability and are therefore used in particular in the construction industry to create load-bearing structures for buildings, bridges, towers and other structures. The best-known types of beams are I, U, L, T and double-T beams, which guarantee a particularly high load-bearing capacity thanks to their shape. Laser cutting of beams is a very precise processing method and offers a high degree of accuracy and repeatability. Time-consuming reworking, which is sometimes necessary with conventional production methods, can usually be dispensed with.

Laser cutting of pipes

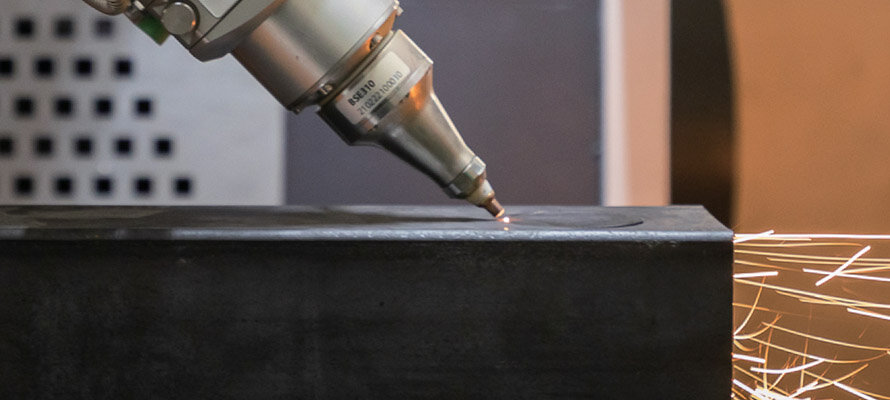

Pipes have a hollow cylindrical structure and are usually made of inflexible materials such as metal, plastic or glass. They are used in particular as supply lines for the transportation of liquids or gases or in the construction industry for scaffolding, balconies, banisters and more. Metal pipes often have to be welded to other workpieces. Thanks to the laser cutting process, weld seam preparations can also be made reliably in openings or recesses.

Advantages: Laser cutting of pipes, profiles and beams

- Precise cuts with minimal tolerances

- Processing of a wide range of different materials

- Cutting of complex shapes and contours

- High production speed and efficiency

- Minimal deformation of the materials

- High automation potential

Areas of application for the laser cutting of pipes, profiles and beams

The laser cutting of pipes, profiles and beams is used in a wide range of industries:

- Automotive industry: production of frames, exhaust systems and safety structures

- Aerospace: complex pipes and profiles for structural components, engines and other parts of aircraft

- Construction industry: manufacture of steel structures, railings, stairs, beams and other architectural components

- Furniture industry: construction of steel furniture such as tables, chairs, shelves and bed frames

- Power generation: components for wind turbines, solar plants, power plants and other energy generation facilities

- Medical technology: production of medical devices, surgical instruments and implants

- Food industry: pipes and profiles for processing plants, conveyor belts and other equipment

- Electronics industry: production of housings, heat sinks and holders

These applications are just a few examples, and the use of laser cutting technologies for the production of pipes, profiles and beams in various industries is steadily increasing due to their precision, speed and versatility.

Pipe, profile and beam processing using fiber laser technology

The MSE TubeFL series

Reliable and fast 2D and 3D processing of pipes, profiles and beams. The MSE TubeFL is a compact and efficient solution for the production of high-precision parts and, depending on the version, has an extremely high degree of automation.

- Pipe & profile processing

- Beam processing

- 2D cutting

- Bevel cutting

- Marking

- Material handling

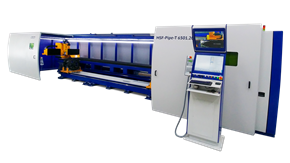

The MSF Pipe series

Pipe and profile processing at high cutting speeds. The MSF Pipe can be used to realise the finest contours and openings as well as precise bevel cuts. An optional extension for processing sheet metal is also available.

- Sheet processing

- Pipe & profile processing

- 2D cutting

- Bevel cutting

- Marking

- Scanning

- Automation

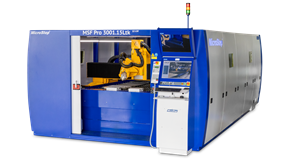

The MSF Pro series

The MSF Pro series can be used to cut sheet metal as well as pipes and profiles. The precise laser all-rounder scores with both multifunctionality and high cutting speed.

- Sheet processing

- Pipe & profile processing

- 2D cutting

- Bevel cutting

- Drilling, Tapping, Countersinking

- Marking

- Scanning

- Material handling

- Automation

Laser cutting tubes, profiles and beams in action

The MSE TubeFL laser series from MicroStep Industry offers a wide range of production options up to a laser power of 15 KW.

You might also be interested in:

FAQ: We answer your questions about laser cutting tubes, profiles and beams

What lengths of tubes, profiles and beams can be cut with laser cutting systems from MicroStep Europe?

The laser cutting systems from MicroStep Europa enable the precise processing of tubes up to 12.2 meters in length and 580 mm in diameter. Square profiles can also be processed up to a length of 12.2 meters and an edge length of up to 500 mm. The length to be processed depends on the machine type and the respective design.

What shapes and geometries can be cut with the laser cutting systems from MicroStep Europe?

MicroStep Europa's laser cutting systems for tubes, profiles and beams cover a wide range of shapes and geometries: square tubes, round tubes, elliptical tubes, flat tubes and triangular geometries as well as I-beams and other material shapes can be clamped and processed without any problems. There are virtually no limits to the geometries and shapes that can be cut with laser processing.

What material types and thicknesses of tubes, profiles and beams can be cut with laser cutting systems from MicroStep Europe?

As with the laser cutting systems for flat material, the laser cutting systems for tubes, profiles and beams from MicroStep Europa can also process numerous types of material, in particular metals such as steel, stainless steel or aluminum. The maximum material thickness to be cut depends on the respective laser source. MicroStep Europa's laser machines for tubes, profiles and beams are available with outputs of up to 15 kW.

What automation options are available for MicroStep Europa's laser cutting systems for tubes, profiles and beams?

Depending on the design of the laser cutting systems, they have an extremely high degree of automation:

- Fully automatic loading and unloading system incl. parts sorting

- Automatic focus position adjustment according to the material to be cut

- Automatic distance calibration and cleaning of the nozzle

- Automatic nozzle change

- Automatic cutting waste disposal

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization