MSLoop

Multiplier for processing

of sheet metal

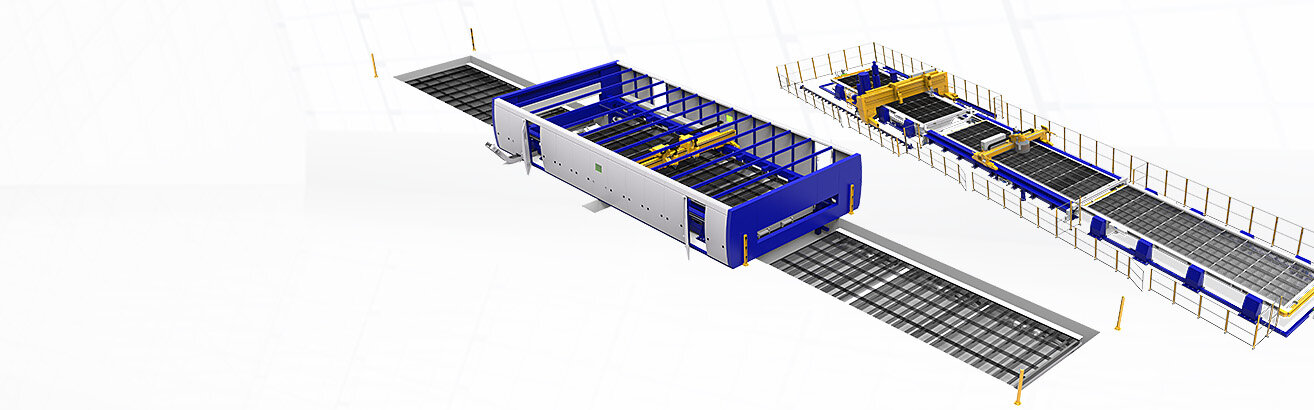

MSLoop | The intelligent shuttle table system

MSLoop is a shuttle table system, consisting of several cutting grids, which significantly increases the throughput of CNC cutting machines, as the system allows simultaneous loading, cutting and unloading. The principle of the system is that three shuttle tables rotate in an endless loop: One table is first loaded, then moves into the processing zone and after cutting into the unloading zone – after complete unloading, the table finally moves under the cutting system back into the loading zone. The table size can be configured modularly from 3.0 m in 1.5 m units.

Optionally, a technology for pre-processing the material can be integrated in the loading zone, for example to apply markings or remove primer from surfaces. To further automate and accelerate the production process, MSLoop can be combined with an automatic material handling system. Maximum productivity is achieved by the shuttle table solution in combination with MicroStep's MPM production management software.

Features

MSLoop: Universally applicable in plasma and laser applications

MSLoop can be combined with MicroStep cutting systems equipped with plasma or laser cutting technology…

Reduced downtimes: Synchronous loading, processing and unloading

The system consists of three separate work areas that allow simultaneous loading/unloading and pricessing of workpieces, e.g. ....

Optimized safety: technology protects the operator

Jede Zone verfügt über einen separaten Zugang in den umzäunten Bereich, der erst entriegelt wird, nachdem alle Maschinen...

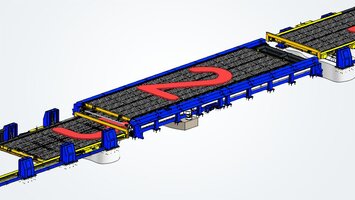

Fume extraction and scrap collection

A fume extraction and scrap collection wagon moves under the gantry between the upper and the lower bed to collect remains from...

Convenient material handling

To fit seamlessly into any production facility, MSLoop does not have to stand on the floor. The embedded version with tables...

Software

Software from MicroStep® – developed especially for cutting

To allow you to concentrate fully on your production, our MicroStep® software solutions, drawings and cutting plans help you to intuitively convert them into finished components. Part of our product range also includes automation solutions for the organization of your entire cutting process.

MPM Production Management

MPM forms the basis for automated cutting. It automatically nests complex cutting jobs and projects on the right material and distributes the cutting plans to cutting machines for processing.

Media

MSLoop

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization