Laser cutting automotive industry

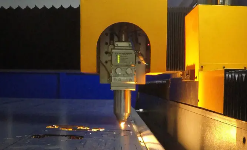

For suppliers and manufacturers in the automotive industry, fast processing and delivery times with maximum quality are essential in order to remain competitive. Laser cutting is the ideal processing method for the automotive industry, offering maximum precision at the highest possible speed. The process enables extremely precise and accurate cuts with tight tolerances, which is particularly important in the production of complex components. The versatility of laser technology allows the cutting of various materials such as steel, aluminum, titanium and plastic, which are frequently used in automotive production. Another advantage is that the cutting edges often require virtually no reworking, which reduces processing time and costs. Both for the production of prototypes and in series production, laser cutting systems offer an extremely high degree of flexibility in order to meet individual customer wishes and high requirements. Laser cutting is used in the automotive industry for the production of body parts, frames, dashboards and cladding, among other things.

FAQ: We answer your questions about the laser cutting automotive industry

What is laser cutting and how is it used in the automotive industry?

Together with oxy-fuel cutting, plasma cutting and waterjet cutting, laser technology is one of the four key cutting processes in metal processing. Laser cutting technology in particular is often used in the automotive industry, as a variety of materials can be cut precisely and at the highest possible speed in order to meet the high demands of automotive industry customers in terms of precision and quality.

Which materials can be processed with laser cutting in the automotive industry?

The manufacture of a vehicle requires a wide variety of components such as bodywork, frames, exhaust systems and safety structures, which in turn are made from a wide range of materials such as steel, aluminum and plastic. Laser technology is suitable for cutting through numerous materials and enables them to be processed at a comparatively high cutting speed compared to other technologies.

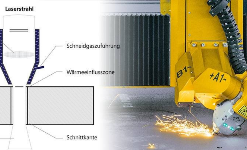

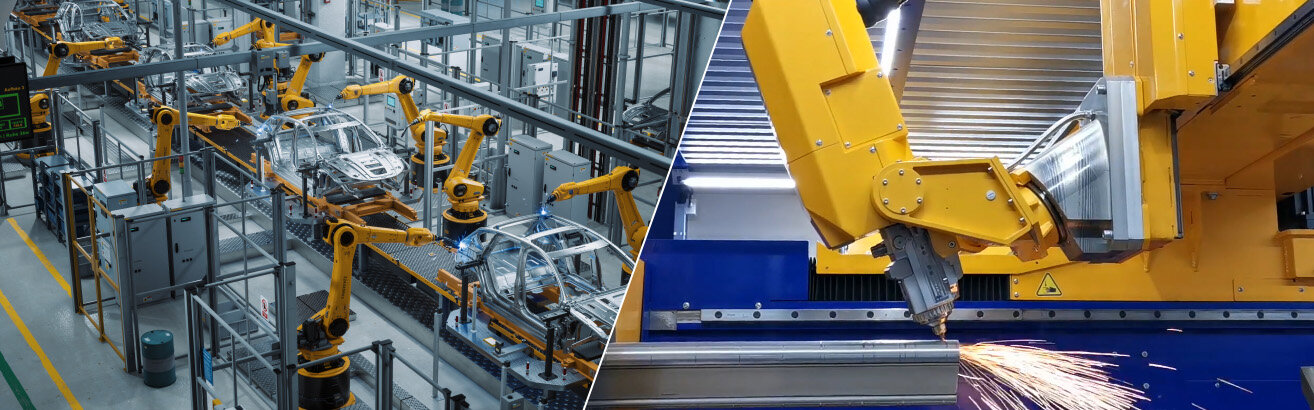

What are the advantages of robot-guided cutting technology in the automotive industry?

Due to the high automation requirements in the automotive industry, fiber-guided laser systems are particularly suitable for use in robot-guided cutting systems, as they offer a high degree of flexibility for a wide range of cutting applications and materials. Non-contact, low heat input and a process that requires virtually no post-processing are additional advantages that speak in favor of their use.

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization