How does laser cutting work?

Laser cutting is a proven and constantly developing technology that is used in many industries. Modern laser cutting machines enable the precise and fast cutting of different materials. Cutting aluminium is no exception. Do you need a 2D or 3D laser system? Then MicroStep is the right choice for you! We look back on 30 years of know-how in the development of our CNC cutting machines.

Laser cutting - everything you need to know at a glance

Laser cutting is a thermal cutting process. The materials to be cut are vaporised or melted with the help of a laser beam. Today, laser sources of different wavelengths make it possible to cut materials of almost all material groups with millimetre precision and thus at the highest quality level – no matter if it is paper, plastic, metal, glass, wood or other materials. The laser cutting process is extremely efficient due to its precision and speed as well as its low post-processing cutting results. It is particularly well-known and also economical in metal processing, where, for example, metal and steel have to be cut in relatively thin material thicknesses with maximum precision and at the highest possible processing speed. With the progressive development of laser sources and ever greater laser powers available, it is also possible to process ever greater material thicknesses economically.

Laser cutting is a thermal cutting process. The materials to be cut are vaporised or melted with the help of a laser beam. Today, laser sources of different wavelengths make it possible to cut materials of almost all material groups with millimetre precision and thus at the highest quality level – no matter if it is paper, plastic, metal, glass, wood or other materials. The laser cutting process is extremely efficient due to its precision and speed as well as its low post-processing cutting results. It is particularly well-known and also economical in metal processing, where, for example, metal and steel have to be cut in relatively thin material thicknesses with maximum precision and at the highest possible processing speed. With the progressive development of laser sources and ever greater laser powers available, it is also possible to process ever greater material thicknesses economically.

The technical process of laser cutting

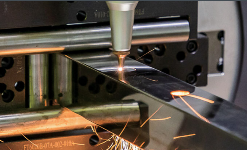

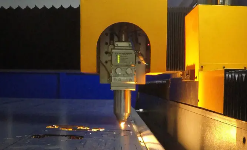

In CNC laser cutting the laser beam is focused with the help of optical elements located inside a cutting head. In order to start a targeted laser cutting process, the material to be cut must be penetrated in a punctiform manner at a previously defined point. This process is also called the piercing process. Once this has been done, the actual cutting process can start. The beam is absorbed at the cutting front and generates a melt (also called metal vapour or material vapour), which is blown out downwards by means of a gas stream immediately after its formation. A process gas is usually required for laser cutting. Depending on the cutting process, oxygen, nitrogen or air are usually used as cutting gas. What remains is a cutting gap, which can have different widths depending on the cutting method used, the material thickness and the design of the optical system. The laser system travels along the previously defined geometry and cuts the material.

What laser cutting processes are available?

Basically, a differentiation is made between three laser cutting processes, namely laser flame cutting, laser fusion cutting and laser sublimation cutting. The distinguished criteria for this is the way in which the material to be cut is removed from the kerf, namely whether in the form of steam, as an oxidation product or as a liquid.

In addition to the three separation processes mentioned above, thermal laser separation and scribing are also evaluated as laser cutting processes.

Overview of relevant laser cutting processes

Which laser cutting process is used depends largely on the material to be processed:

Flame cutting

Laser cutting is one of the most frequently used processes in laser cutting technology and is mainly used for cutting structural steel. In these laser cutting processes, oxygen is used as the cutting gas, whereby the material burns during the cutting or melting of the material, which is heated to ignition temperature by the laser beam (due to the reaction with the oxygen). The reaction of the oxygen with the material is exothermic and thus supplies additional energy to the process, which favours the cutting process. With flame cutting, it is therefore possible to achieve significantly higher cutting speeds with greater sheet thicknesses than with fusion cutting with the same laser power. An oxide layer is formed on the cut edge by the oxygen used. This layer can cause problems in subsequent production steps such as welding, coating or painting, etc., making it necessary to remove the oxide layer (spelling derived from the Greek: Oxydschicht). An important factor for the quality of the cut edge and the speed of laser cutting is the purity of the oxygen. In order to achieve a consistent and good cut quality, this should not be less than 3.5. This means that it has a purity of ≥ 99.95 %.

Fusion or high-pressure laser cutting

Fusion cutting uses inert gases such as nitrogen or argon with pressures up to 25 bar. Since these gases do not react with the material, the entire thickness of the material must be melted by the laser beam. The high gas pressure then causes the molten material to be driven out of the kerf at high speed. This prevents the formation of a burr and the adhesion of slag to the cut edges over a large thickness range to the greatest possible extent. Since there is no exothermic reaction between material and gas, no additional energy is added. By using inert gases as cutting gas, the cutting edge remains free of oxides. Colloquially, cutting with non-reactive gases (due to the high pressure used and required) is also referred to as high-pressure cutting and is usually used where bright metallic cut surfaces must be achieved. The main area of application is the cutting of stainless steel and aluminium as well as the cutting of thinner structural steels.

Sublimation cutting

The process of sublimation cutting is based on the vaporisation and blowing out of the material during the cutting process. This means that the material to be processed changes from a solid state, without becoming liquid, to a gaseous state at the kerf. In addition to inorganic materials, sublimation cutting can also be used to cut organic materials reliably and precisely. Materials used for this cutting process include wood, leather, textiles and homogeneous and fibre-reinforced plastics. A typical feature of this process is that there is no need for time-consuming mechanical reworking of the sublimation cuts made, as no burrs are formed during sublimation cutting. Vapours are generated during the cutting process. A cutting gas, for example nitrogen, is used to prevent heavy smoke development or flaming of the materials to be cut. At the same time, the cutting gas also prevents the vapours from condensing on the cutting edge.

Laser cutting Application areas

Due to the fact that the cutting of different materials with the help of a laser cutting system (despite the relatively high acquisition costs) is very productive and extremely economical, the areas of application are wide-ranging; not only in industry and production, but also in everyday non-industrial areas of application. Laser cutting is used in vehicle and aircraft construction, in the electrical industry, in arts and crafts, in medical technology, for jewellery production, in vending machine construction as well as for stamp production and in the textile and fashion industry as well as in many other areas.

It is a fact that the areas of application and possible uses of laser cutting are continuously being expanded and are the subject of many projects in science and research. It is also a fact that the possibilities of laser cutting technology are by no means exhausted. Particularly in the field of fibre laser technology, ever greater and more variable material thicknesses can be cut with the constantly developing laser sources. Due to the parallel and constantly increasing degree of automation, for example by using the potentials within material handling, the advantages of ever shorter processing times can be optimally exploited through the use of laser cutting systems.

Laser cutting industry - materials

In laser cutting, we are talking about so-called industrial lasers, which have already established themselves in many areas and are now almost unrivalled in terms of efficiency. The highly developed technology of industrial lasers replaces other tools, as the precision and cutting quality of laser cuts requires virtually no post-processing. The following metals are primarily cut with lasers:

In laser cutting, we are talking about so-called industrial lasers, which have already established themselves in many areas and are now almost unrivalled in terms of efficiency. The highly developed technology of industrial lasers replaces other tools, as the precision and cutting quality of laser cuts requires virtually no post-processing. The following metals are primarily cut with lasers:

- Structural steel

- Stainless steel

- Aluminium

- Copper

- Brass

Cutting with CO2 lasers is increasingly only used for specific applications, such as cutting wood, Plexiglas or plastics.

The reason for this lies in the different suitability of the various wavelengths of laser radiation for the respective material. The selection of the ideal laser (type of laser / wavelength and its power) is the most important factor for optimal production at the lowest possible cost.

Construction of laser cutting systems

A laser cutting system always consists of several components, which are briefly listed below:

- Laser beam source: A beam source essentially consists of an energy source, a laser medium and a resonator, whereby the various laser types differ greatly in the structure and design of the individual components.

- Laser beam guidance: The beam guidance has the task of transporting the laser beam from the beam source to the processing head with as little loss as possible.

- Guiding machine The guiding machine contains all axes, motors, servos, controllers as well as controls and software that are needed to ensure the subsequent movement and control sequence of the cutting process. The axes are divided into X, Y (travel axes of the respective working area) and Z (feed axis of the cutting head).

- Cutting head: The incoming laser radiation is focused in the cutting head and made available for the respective cutting process according to the application data. In addition to the focussed laser radiation, the cutting gas for the respective cutting process also emerges from the cutting head's exit opening. The cutting gas is formed within the cutting nozzle, which is usually made of copper.

- Gas supply: A gas supply provides the gases required for the cutting process as well as auxiliary gases needed for the function of the laser or the machine.

- Extraction and filter system: The extraction system extracts the gases and particles produced during the cutting process and separates them. Material particles and dusts are collected in a container, and the cleaned air is returned to the environment.

- Cooling: To prevent overheating or destruction of individual components, these are cooled with the aid of a cooling circuit. This mainly concerns the laser beam source, the laser beam guidance and the cutting head of the system.

- Enclosure: In order to comply with all safety standards, laser systems are provided with an enclosure and a safety area; to protect employees from the dangers of fast-moving parts and from possible laser radiation.

Special cutting heads and additional motion axes are used for 3D laser cutting. These can be swivelled in 3D, i.e. to both sides as well as towards and away from the portal. This enables flexible and spatial processing of the material up to angles of 45°.

You might also be interested in:

FAQ: We answer your questions on "How does laser cutting work?"

What cutting widths are possible with laser cutting?

Here you first have to distinguish which type of laser cutting you are dealing with. As a rule, laser flame cutting produces larger kerfs than laser fusion cutting. In addition, the cutting width also depends on the optical design of the system and the thickness of the material to be cut. As a general rule, the kerf is smaller for thinner materials than for thicker materials. In the fine cutting range and in micromachining, cutting gaps in the lower micrometre range are feasible. In industrial metal processing of sheets above 1 mm, kerf gaps of about 0.3 mm to 3 mm are quite possible. A general characteristic of a laser cut is the almost vertical course of the cut edge.

Laser cutting vs. plasma cutting - what are the advantages?

Both laser cutting and plasma cutting have specific advantages. Depending on the application, both can be the optimal means of choice in terms of economy, accuracy and efficiency. For example, medium material thicknesses of 20 to 50 mm can be cut with plasma with good quality and economic efficiency and at higher cutting speeds. The demands on the material to be processed and its surface are also generally lower with plasma, as are the demands on the working environment. In contrast to lasers, plasma has limitations when cutting small contours and a relatively wide kerf. In addition, there is a high noise level during plasma cutting and the fact that only electrically conductive materials can be cut. Plasma systems are cheaper to purchase than laser systems, although this difference has narrowed considerably in recent years.

Especially in the thinner sheet thickness range up to 10 mm, the advantages of the laser are clearly visible. The cutting speed is sometimes considerably faster, the cut quality is better, much more precise contours can be cut and this with much less noise pollution and with smaller cutting gaps. The automation of a laser system is also much higher.

The cost consideration between plasma cutting and laser cutting per cutting metre depends on very many factors and is therefore always dependent on the respective application. In principle, the cutting costs are lower in the thin sheet area with laser and in the thick sheet area with plasma. Due to the steadily increasing laser power for cutting and the decreasing prices per kW laser power, the intersection of these two curves is also shifting.

How much time does a laser system need until the cutting process can be started?

When all individual components of the system are switched on, all auxiliary media are available (cutting gases, compressed air), the programme to be executed is loaded, all parameters are correctly set, the system is referenced and the laser is ready to beam, then the cutting process can be executed or started. The time it takes for the laser to be ready to beam differs greatly between fibre lasers and CO2 lasers. While a fibre laser is a purely electronic laser that is ready to beam immediately after switching on and starting up the internal control, a CO2 laser must first go through a longer start-up cycle until it reports that it is ready to beam. Such a start-up cycle can take between 5 and 20 minutes; even longer in the case of longer downtimes. With modern fibre laser systems, it sometimes takes less than 5 minutes after switching on the main switch until the first cut is made.

Which font is suitable for laser marking?

Basically, any font can be used with laser systems, be it for cutting or for inscribing, as it is a CNC programming and the individual fonts can be converted into a cutting programme accordingly. Furthermore, MicroStep also offers CNC cutting systems that are equipped with so-called marking lasers. These separate systems offer significantly higher flexibility and speed in marking and labelling for special required labelling tasks (QR code, etc.).

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization