Lasers cutting aluminum

Laser cutting is used on a wide variety of materials to cut filigree contours quickly and precisely. Due to the nature of different alloys, cutting aluminum is a more complex process compared to other metals. Modern systems, especially fiber lasers, have the necessary requirements to achieve high quality results.

What types of aluminum can be processed by laser?

There are different types of aluminum, or rather aluminum alloys. Depending on the requirements, the pure aluminum extracted from the earth is combined with small amounts of magnesium, manganese, copper, silicon or zinc through various processes in order to combine the advantages of the elements. For example, the extremely light material aluminum is further hardened and additionally protected against corrosion or heat. In principle, any aluminum alloy can be processed by laser cutting. However, depending on the material properties, there are differences in cutting quality, cutting speed and different challenges when cutting.

Advantages: Laser cutting of aluminum

- High accuracy

- Cutting of a wide range of material thicknesses

- Very high speed

- Contactless cutting process

- Wide range of applications

What should be considered for laser cutting of aluminum?

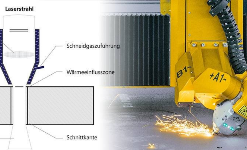

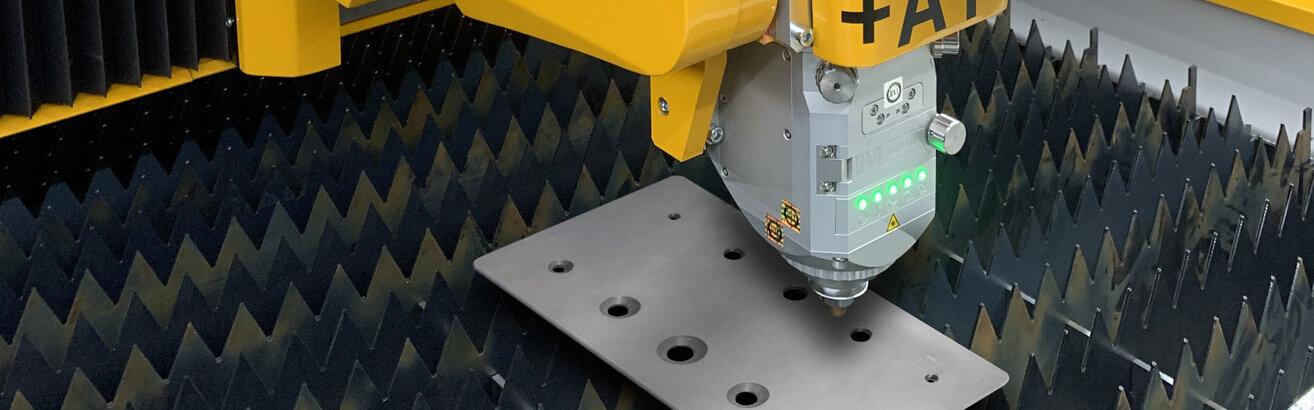

Due to the properties of aluminum (low melting point, strong thermal conductivity), laser cutting of the light metal is a more complex process than for other metallic materials such as mild steel. Depending on the alloy and surface properties, strong reflections can also occur during the piercing process in the material. Nevertheless, precise and fast cuts are possible with modern laser cutting systems in a wide range of sheet thicknesses. This requires sensitive regulation of the piercing process throughout the entire cutting process in terms of speed, kerf width and cutting gas feed. Fiber laser technology in particular is used to overcome the challenges of aluminum cutting and achieve high quality results.

Advantages of laser cutting of aluminum

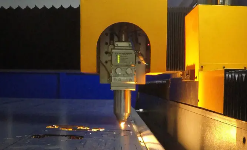

Aluminum and its alloys are indispensable materials in industrial manufacturing. As with cutting other materials, laser cutting is almost without alternative when producers are looking for a solution for thinner sheet thicknesses where tight, dross-free contours need to be cut quickly with exact reproducibility. The dross-free quality of the cut parts depends on the particular alloy and material thickness to be cut, as well as on the laser power used. Even complex geometries with tight radii can be cut with this cutting process. If, on the other hand, milling or punching is used for aluminum processing, depending on the technology, limitations in flexibility, precision as well as economic efficiency down to the smallest batch sizes must be accepted. Fiber lasers, in particular, also score points here with lower maintenance and operating costs. Aluminum can also be cut with oxyfuel or plasma torches, but lower accuracies are possible here and the high thermal conductivity of the material plays an even greater role.

Where is laser cutting of aluminum used?

The cutting of aluminum with laser technology is required and profitably used in numerous and different industries: This starts with the automotive industry and in classic contract cutting, continues with metal, machine and plant construction, facade or tool making, and extends to medical and laboratory technology as well as the IT and electronics sectors.

Aluminum: What is this actually?

Aluminum is a chemical element that was discovered in 1754 and was only used for industrial purposes in the 19th and 20th centuries. Aluminum is the third most common metal in the earth's crust. The light metal is silvery-white in color and usually occurs not in pure form, but as bound aluminum ore. The most common ore is bauxite, from which aluminum is obtained by energetic processes. By alloying it with other elements, the properties of the light metal can be changed and the resulting molten metal can be shaped. Aluminum is a very light metal, has high corrosion resistance, stability and fire resistance, is electrically conductive and recyclable.

You might also be interested in:

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization