MSF Pro series

The exclusive high-speed solution

for advanced laser cutting

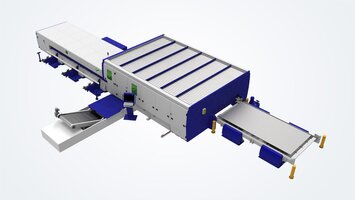

The MSF Pro | Multifunctional 3D fiber laser cutting machine with a high automation level

MicroStep‘s precise laser all-rounder MSF allows for multi-functional processing of materials: 2D and 3D cutting of sheets with bevels up to 50°, drilling, tapping, countersinking as well as marking. The machine can be equipped with a turret drilling head for 6 tools that allows drilling up to 20 mm in diameter and tapping up to M16. Optionally, the cutting area can be extended by a pipe & profile cutting zone for processing of pipes up to 500 mm in diameter and a length up to 12 m, or hollow sections up to the size 350 x 350 mm.

Thanks to the patented ACTG® technology, MSF machines deliver consistent, highly precise bevel cutting results in a reliable process with minimum maintenance downtimes. Another innovative technology – ABP – offers the option of adding bevels to already cut parts, for example to thicker workpieces that were cut with plasma in advance. By default, MSF machines are equipped with automatic shuttle tables, whereas automatic material handling and sorting options for sheets, pipes and profiles are likewise available.

MSF machines are designed for production of highly accurate parts at high cutting speeds, with surprisingly low maintenance and operational costs. The outstanding dynamics of the MSF Pro series is achieved by a low-seated gantry, digital AC drives and precise planetary gears. The machines are equipped with state-ofthe- art fiber laser sources of powers up to 30 kW.

These customers rely on MicroStep and benefit from the MSF Pro

"The new solution enables us to meet the market’s high demands in regards to both the quantity of ordered parts and their quality, which is vital since the cut parts are further being processed at a robotic welding station."

Ing. Mgr. Kristína Koláriková Kulichová,

Managing Director | Hykemont spol. s r.o.

Features

The perfect solution for fast and precise cutting

A powerful, compact laser cutting machine for cutting a wide variety of materialsHigh precision and accuracy of parts and...

Robust, dynamic, and long-lasting machine design

Gantries with extremely high torsion resistance enable high traverse speeds of up to 180,000 mm/minBellows on all axes protect...

Extensive automation features and options

Shuttle table with fast table changeover reduces costly downtimesAutomatic focus position and diameter adjustment according to...

Laser bevel head for bevel cuts up to 45°

Simple V- and X-bevels as well as complex Y- or K-bevels up to 45° with micro jointsClean and efficient weld edge...

High economic efficiency

2/3 lower power consumption and higher cutting speeds (compared to CO2 laser of the same power)The complete machine is nearly...

Automatic cutting waste disposal

A conveyor belt transports the small parts that have fallen off the work table or the cutting waste into a separate container...

Pipe and profile cutting

Various pipe and profile cutting options in combination with sheet processing or as a standalone pipe cutting solutionCutting...

Laser bevel head for bevel cuts up to 45°

V- and X-bevels as well as complex Y- or K-bevels up to 45° with micro jointsAuto-calibration of tool geometry (ACTG®...

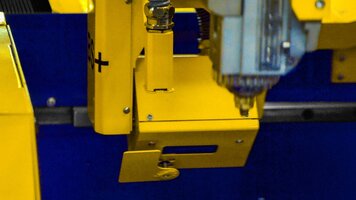

Fully automatic drilling up to Ø 20 mm and tapping up to M16

Fully automatic drilling solution for laser machinesDrilling up to Ø 20 mm, tapping up to M16 and countersinkingTurret head...

Combination solution: Automated sheet, pipe and profile handling

For MicroStep’s laser cutting system MSF Pro different handling solutions for different cut parts are available. The system can...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

Dimensions |

|

| Effective length of work area* | 1,000 to 15,000 mm |

| Effective width of work area* | 1,500 to 3,000 mm |

| Automatic shuttle table | included as standard |

| *Different configurations on request. Without shuttle table, other desired table dimensions can also be realized. The net area of the working zone can be operated with all available tools. | |

Tools |

|

| Possible number of tools | 2 |

| Possible cutting processes | fiber laser |

| Maximum material thickness | according to laser source |

Pipe and profile cutting |

|

| Minimum diameter of pipe | from 20 mm |

| Maximum diameter of pipe | up to 500 mm |

| Minimum dimension of profile | 14 x 14 mm |

| Maximum dimension of profile | 350 x 350 mm |

| Maximum wall thickness | according to laser source |

| Minimum length of pipe | 500 mm |

Drilling |

|

| Drilling up to | Ø 20 mm |

| Tapping up to | M16 |

| Maximum number of tools | 6 |

| Tool change | hydraulic |

| Maximum speed of spindle | 5,200 rpm |

| Axial force | 3,000 N |

| Duration for toll change | < 1 Sec. |

| Pressure force holder | 1,170 N |

| Lubrication, cooling | external, oil – aerosol |

| Nominal torque | 21 NM |

Precision |

|

| Traverse speed | up to 180,000 mm/min. |

| Positioning speed Z axis | up to 50,000 mm/min. |

| Positioning accuracy Pa | 0.07 mm according to VDI/DGQ 3441 |

| Repeatability Ps | 0.03 mm according to VDI/DGQ 3441 |

| X, Y axis | linear guides, driven on both sides and helical toothed racks |

| Z axis | rack |

| Gantry type | massive steel gantry |

Control & software |

|

| Control | iMSNC® |

| Main control panel | ergonomic 24" touchscreen control panel |

| Operating system | Windows 11 Pro (64-bit) |

| Additional operating units | portable operating unit (mounted on the main control panel) |

| All specifications subject to change | |

Software

Software from MicroStep® – developed especially for cutting

To allow you to concentrate fully on your production, our MicroStep® software solutions, drawings and cutting plans help you to intuitively convert them into finished components. Part of our product range also includes automation solutions for the organization of your entire cutting process.

Asper Basic

Asper Basic is the ideal tool for an easy and fast creation of NC programs for different cutting technologies (plasma, oxyfuel, laser or waterjet).

Asper Nesting

With Asper Nesting, you can easily and intuitively nest component drawings into efficient cutting plans.

MicroStep mCAM

mCAM is an efficient tool for the automated 3D production on pipes, profiles, domes, IPE carriers but also flat sheets with cutting systems of different technologies.

MPM Production Management

MPM forms the basis for automated cutting. It automatically nests complex cutting jobs and projects on the right material and distributes the cutting plans to cutting machines for processing.

Control

Handles even the most complex cutting tasks – the iMSNC® machine control

iMSNC® from MicroStep is one of the most advanced control systems for CNC cutting machines. It was developed to easily, reliably, and efficiently turn cutting plans into finished parts with the help of a clear and modern user interface.

MSF CyberFab® machine control

Intelligent solution for cross-technology work with the laser cutting system

The system consists of a stand-alone control console with a 24" TFT touchscreen monitor. If cameras are implemented in the interior, the existing touchscreen can be supplemented with an additional screen for displaying live images. In order to achieve maximum utilization and flexibility of our machines, the ergonomic control console offers you the possibility – parallel to running cutting processes – to nest new cutting programs and generate additional CNC codes. As the CyberFab® control system and all CAM software solutions come from our company, the software with its versatile modules can be individually customized for your production. Parameter databases for individual technologies enable consistently high quality under various circumstances. CyberFab® comes with multiple efficient evaluation tools for production process optimization. These provide you with the much-needed overview of current cutting orders, cutting times, cost calculations and machine utilization in day-to-day production.

Overview of important performance data:

- MMi console and 24’’ touchscreen

- Display of existing cameras in the interior via additional screen (optional)

- Efficient management of tool data

- Very short programming times

- Fast data transfer

- Flexible and easy to use

- Advanced cutting simulation for more work safety

- Convenient contextual help via pop-up bubbles

Media

Video: Overview of the MSF series

Cutting system

2D cutting

3D cutting

Automated material handling

Marking

Scanning

Pipe and profile processing

Control and operating unit

Cutting samples

Other options

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization