MSF Cut

Reliable laser performer

for 2D standard tasks

The MSF Cut | Reliable 2D performer for laser cutting

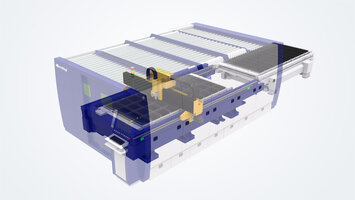

When it comes to precise and process-safe completion of 2D cutting tasks, the MSF Cut is the right choice. Because the laser for standard 2D tasks is a reliable performer and with its strengths focuses on precision, cost-effectiveness and efficiency. The new series for fast and precise sheet metal processing is available in three formats with working areas of 3,000 x 1,500 mm, 4,000 x 2,000 mm and 6,000 x 2,000 mm. Laser sources with a power of up to 15 kW are available.

High-quality brand components combined with MicroStep's proven smart control and software ensure high reliability and lasting reproducibility of the precise cutting results. Thanks to the attractive pricing with comparatively low investment and operating costs, a fast return on investment is given.

The MSF Cut is more than a modern laser cutting system with high-quality components: The system is already well equipped for the manufacturing of the future! Because the fiber laser cutting system is optimized for the use of IndustryFusion, a manufacturer-independent open source networking solution for smart factories and smart products.

Features

The MSF Cut: High-quality 2D laser cutting, process-safe & efficient

The MSF Cut is an efficient fiber laser cutting system that combines reliability, precision and economy. The modern 2D cutting...

High efficiency in spite of strong performance

Highly attractive pricing with comparatively manageable investment and operating costs enables a fast return on investment ...

High-quality components from renowned brand manufacturers

High-quality brand components combined with MicroStep's proven smart control and software ensure high reliability and lasting...

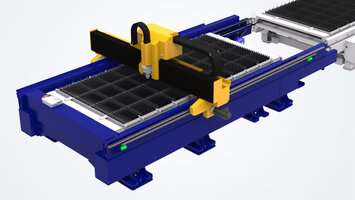

Highly dynamic, massive machine gantry

To ensure high rigidity despite low weight, the gantry bridge is based on welded structural profiles. This combination in...

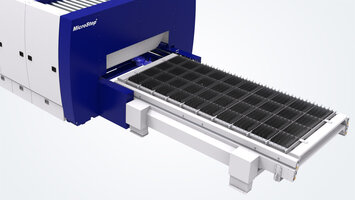

Automatic shuttle table with sectional extraction

The fiber laser cutting system is equipped with an automatic, motor-driven shuttle table as standard. The shuttle table system...

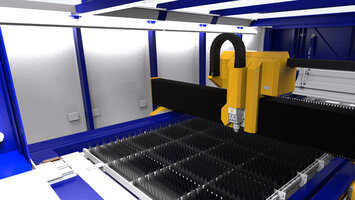

Outstanding cutting quality - whatever the cutting job

The MSF Cut achieves outstanding cutting quality – regardless of the materials and component geometries to be cut. Due to...

Efficient processing with a high degree of automation

Several smart tools help to achieve consistently precise and efficient 2D cuts. Not only does the shuttle table system enable...

Smart today and also tomorrow – Fiber Laser Cutting 4.0 with the Green SmartFactory

The standard equipment of the MSF Cut includes software tools and interfaces that simplify the daily production process and...

More automation, more efficiency

Additional automation solutions are available for the MSF Cut laser cutting system for even higher efficiency. MSF Cut can be...

Remote Diagnostics

With CyberFab® and numerous remote maintenance modules, MicroStep offers the best foundation for fast and competent help...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

Dimensions |

|

| Effective length of work area* | 3,000 to 6,000 mm |

| Effective width of work area* | 1,500 to 2,000 mm |

| Automatic shuttle table | included as standard |

| *Different configurations on request. The net area of the working zone can be operated with all available tools. | |

Tools |

|

| Possible number of tools | 1 |

| Possible cutting processes | fiber laser |

| Maximum material thickness | according to laser source up to 15 kW* |

|

*Higher laser power on request |

|

Precision |

|

| Traverse speed | up to 180,000 mm/min. |

| Positioning speed Z axis | up to 50,000 mm/min. |

| Positioning accuracy Pa | 0.07 mm according to VDI/DGQ 3441 |

| Repeatability Ps | 0.03 mm according to VDI/DGQ 3441 |

| X, Y axis | linear guides, driven on both sides and helical toothed racks |

| Z axis | rack |

| Gantry type | massive steel gantry |

Control & software |

|

| Control | iMSNC® |

| Main control panel | ergonomic 24" touchscreen control panel |

| Operating system | Windows 11 Pro (64-bit) |

| Additional operating units | portable operating unit (mounted on the main control panel) |

| All specifications subject to change | |

Software

Asper Basic

Asper Basic is the ideal tool for an easy and fast creation of NC programs for different cutting technologies (plasma, oxyfuel, laser or waterjet).

Control

MSF CyberFab® machine control

Intelligent solution for cross-technology work with the laser cutting system

The system consists of a stand-alone control console with a 24" TFT touchscreen monitor. If cameras are implemented in the interior, the existing touchscreen can be supplemented with an additional screen for displaying live images. In order to achieve maximum utilization and flexibility of our machines, the ergonomic control console offers you the possibility – parallel to running cutting processes – to nest new cutting programs and generate additional CNC codes. As the CyberFab® control system and all CAM software solutions come from our company, the software with its versatile modules can be individually customized for your production. Parameter databases for individual technologies enable consistently high quality under various circumstances. CyberFab® comes with multiple efficient evaluation tools for production process optimization. These provide you with the much-needed overview of current cutting orders, cutting times, cost calculations and machine utilization in day-to-day production.

Overview of important performance data:

- MMi console and 24’’ touchscreen

- Display of existing cameras in the interior via additional screen (optional)

- Efficient management of tool data

- Very short programming times

- Fast data transfer

- Flexible and easy to use

- Advanced cutting simulation for more work safety

- Convenient contextual help via pop-up bubbles

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization