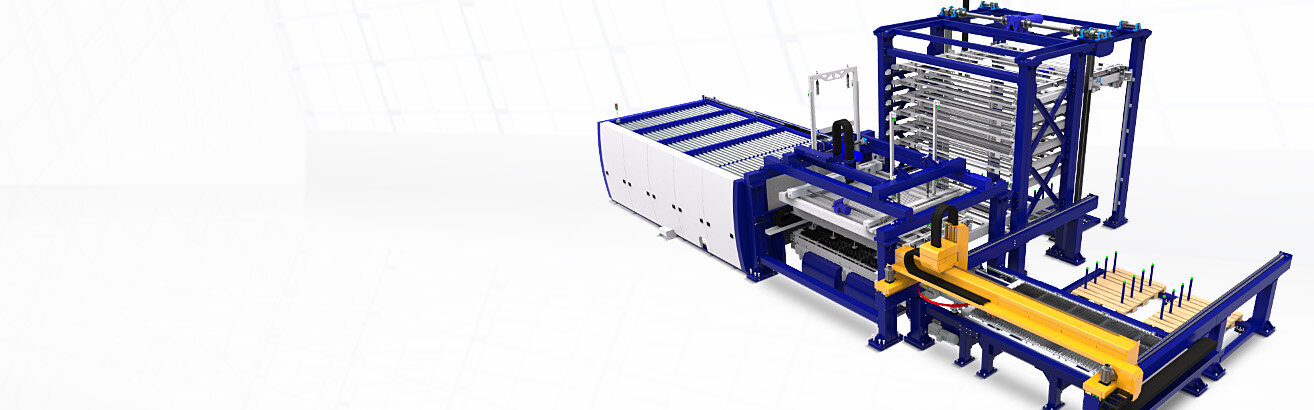

MSLoad, MSTower, MSSort

Reliable technologies: Storage, loading and

unloading of sheets l Sorting of cut parts

MSLoad, MSTower, MSSort

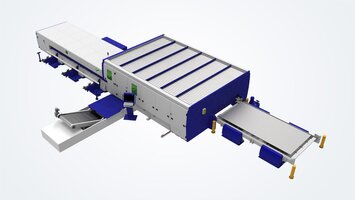

MSLoad is the perfect production assistant taking your production to a new level of automation. The system has a modular design and is used for automatic loading of raw material as well as unloading of cut parts in combination with laser and plasma cutting systems from MicroStep. Combined with the optionally integrable storage system MSTower and the parts sorting system MSSort, the user has a simple and comprehensive solution for the complete material handling.

MSTower is an in-house developed supplement to MSLoad, providing buffer storage close at for raw material and cut material alike.

MicroStep has developed MSSort to separate cut parts from waste material after the cutting process and to sort them according to a customer-defined sorting plan. The automatic sorting system has a customized set of clamping heads, tailored to each part type and stored in a magazine for automatic exchange according to the sorting plan.

Features

MSLoad: Flexible use for different requirements

The variable and modular design of the entire material handling system makes it possible to adapt the technology to all kinds...

MSTower: Customized solutions

The standard MSTower is available in sizes from 3 x 1.5 m to 6 x 2 m and offers space for up to 10 cassettes...

MSSort: Sorting customized to your needs

The MSSort's rotary sorting support has an automatic exchange of gripping tools, each designed to handle different…

Technologies for even more security

Safety is the top priority in material handling. The system is secured by lockable fences and optical barriers that …

Systems for even more efficiency: Automatic nozzle change

In order to increase the degree of automation and thus further enhance productivity, our laser systems can be equipped with an...

Combination solution: Automated sheet, pipe and profile handling

For MicroStep’s laser cutting system MSF Pro different handling solutions for different cut parts are available. The system can...

Software

Software from MicroStep® – developed especially for cutting

To allow you to concentrate fully on your production, our MicroStep® software solutions, drawings and cutting plans help you to intuitively convert them into finished components. Part of our product range also includes automation solutions for the organization of your entire cutting process.

MPM Production Management

MPM forms the basis for automated cutting. It automatically nests complex cutting jobs and projects on the right material and distributes the cutting plans to cutting machines for processing.

Media

MSLoad, MSTower, MSSort

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization