The DRM series

The special system for toughest requirements

The DRM series | The strong specialist

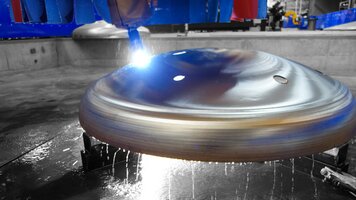

If you are looking for cross-technology work processes, highest precision and reliability for the toughest requirements, the DRM series is the right choice. This strong specialist is a flexible and robust cutting system for almost any cutting task. The plasma cutting system allows 3D processing of sheets, pipes, profiles & domes with extraordinary dimensions.

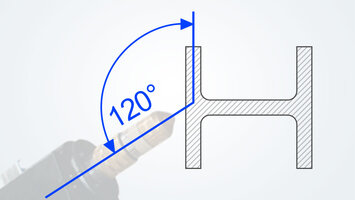

The very stable portal allows a vibration-free operation of heavy technologies such as the 3-torch unit oxyfuel or the special plasma rotator "Pantograph" (120° tiltable) with a Z-axis stroke up to 1,500 mm or several 3-torch units. The heaviest drilling supports up to 55 kW can be realized. The DRM can also be designed as a pure drilling rig with special drilling table.

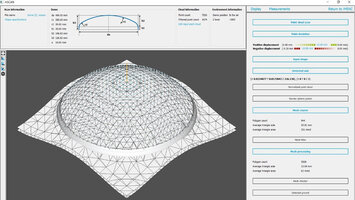

A revolutionary technology has been available since 2016 for an unprecedented quality in dome processing: With mSCAN®, exact contours and high-precision bevel cuts are now standard for domes.

"The systems run and do what they are supposed to do. There's simply no substitute for this dome production machine," says Heiko Kunze, Head of Maintenance at Feldbinder Spezialfahrzeugwerke GmbH.

These customers rely on MicroStep and benefit from the DRM

"After ten years of searching, for the first time we had the feeling that there is someone who wants to sell something that he also knows how to master. Thanks to the omnivalence, the system is in daily use. It replaces two machines, for us that's the optimum."

Konstantin Slawinski,

Managing Director| Slawinski & Co. GmbH

Features

Flexible and robust cutting system for almost any cutting task

The systems of this series enable cross-technology work processes (2D and 3D cutting, drilling, countersinking, tapping and...

Unexceptional precision and reproducibility of cut parts

Cutting is the first step in many production processes. Irregularities on the cut part and loss of precision are inevitably...

Fast and precise bevel cutting with plasma and oxyfuel

Fully automatic and highly precise weld edge preparation with rotator and 3D rotator bevel tool stations with auto-calibration...

3D pipe & profile processing up to Ø 1,500 mm

Enhance your production range by adding a pipe and profile cutting option for processing of a wide range of pipe diameters...

Dome processing up to a diameter of 10,000 mm

This series enables individual and fully automatic dome processing up to 10,000 mm diameter. Depending on the equipment of the...

2D laser with robust, dynamic and long-lasting machine design

Gantries with extremely high torsion resistance enable high traverse speedsCompact, manually extractable cutting table for...

Multi-tool cutting with up to 8 oxyfuel torches

Increase your productivity with parallel cutting operationsPossibility of parallel bevel cutting with several rotator bevel...

Precise dome processing with mScan

MicroStep‘s mScan technology for precise cutting of domes sets new standards in dome processing. A 3D laser scanning...

Best mechanical engineering components from renowned manufacturers

Convincing cutting quality can only be achieved by using high-quality components - that is why we use linear guides on all axes...

Extremely high reliability even in three-shift production

MicroStep systems are designed for a long machine life – sometimes even under tough environmental conditions. The...

Innovative software solutions: Intuitive and easy operation

So that you can fully concentrate on your production, our innovative software solutions help you to intuitively transform...

Ergonomic and uncomplicated: The CyberFab® control system

Apart from the externally positioned control console with ergonomic 24" touch screen display, the system has additional...

Remote Diagnostics

With CyberFab® and numerous remote maintenance modules, MicroStep offers the best foundation for fast and competent help...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

Dimensions |

|

| Effective length of work area* | 3,000 to 30,000 mm |

| Effective width of work area* | 1,500 to 8,000 mm |

| * Different configurations on request. The net area of the working zone can be operated with all available tools. | |

Tools |

|

| Possible number of tools | 4 |

| Possible cutting processes | plasma, oxyfuel |

| Possible number of bevel cutting heads | 2 |

| Maximum material thickness plasma | according to plasma source |

| Maximum material thickness oxyfuel | 200 mm |

Precision |

|

| Positioning speed | up to 40,000 mm/min. |

| Positioning accuracy | according to DIN 28206 / ≤ 0.10 mm/m |

| X, Y axis | linear guides, driven on both sides and helical toothed racks |

| Z axis | ball screw |

| Gantry type | massive steel gantry |

Control & software |

|

| Control | iMSNC® |

| Main control panel | ergonomic 17" touchscreen control panel |

| Operating system | Windows 11 Pro (64-bit) |

| Additional operating units | 2 operating units on the gantry (one on the left side and one on the right side) |

| All specifications subject to change | |

Software

Software from MicroStep® – developed especially for cutting

To allow you to concentrate fully on your production, our MicroStep® software solutions, drawings and cutting plans help you to intuitively convert them into finished components. Part of our product range also includes automation solutions for the organization of your entire cutting process.

Asper Basic

Asper Basic is the ideal tool for an easy and fast creation of NC programs for different cutting technologies (plasma, oxyfuel, laser or waterjet).

Asper Nesting

With Asper Nesting, you can easily and intuitively nest component drawings into efficient cutting plans.

MicroStep mCAM

mCAM is an efficient tool for the automated 3D production on pipes, profiles, domes, IPE carriers but also flat sheets with cutting systems of different technologies.

MPM Production Management

MPM forms the basis for automated cutting. It automatically nests complex cutting jobs and projects on the right material and distributes the cutting plans to cutting machines for processing.

Control

Handles even the most complex cutting tasks – the iMSNC® machine control

iMSNC® from MicroStep is one of the most advanced control systems for CNC cutting machines. It was developed to easily, reliably, and efficiently turn cutting plans into finished parts with the help of a clear and modern user interface.

MicroStep CyberFab® machine control

The intelligent solution for multi-technology work

CyberFab® from MicroStep is one of the most advanced control systems for CNC cutting machines. It was developed to easily, reliably, and efficiently turn cutting plans into finished parts with the help of a clear and modern user interface. The system’s hardware consists of a stand-alone control console with a TFT touchscreen and a control panel with an LCD display mounted on the gantry. In order to achieve maximum utilization and flexibility of our machines, the ergonomic control console offers the opportunity to nest new cutting programs and generate new CNC codes during an ongoing cutting process. As the CyberFab® control system and all CAM software solutions come from our company, the software with its versatile modules can be individually customized for your production. Parameter databases for individual technologies enable consistently high quality under various circumstances. CyberFab® comes with multiple efficient evaluation tools for production process optimization. These provide you with the much-needed overview of current cutting orders, cutting times, cost calculations and machine utilization in day-to-day production.

Overview of important performance data:

- 24’’ touchscreen

- Efficient management of tool data

- Very short programming times

- Fast data transfer

- Flexible and easy to use

- Advanced cutting simulation for more work safety

- Convenient contextual help via pop-up bubbles

Media

Video: Overview of the DRM series

Cutting system

2D cutting

3D cutting

Drilling

Marking

Scanning

Pipe and profile processing

Dome processing

Control and operating unit

Cutting samples

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization