Plasma cutting | Info on plasma technology

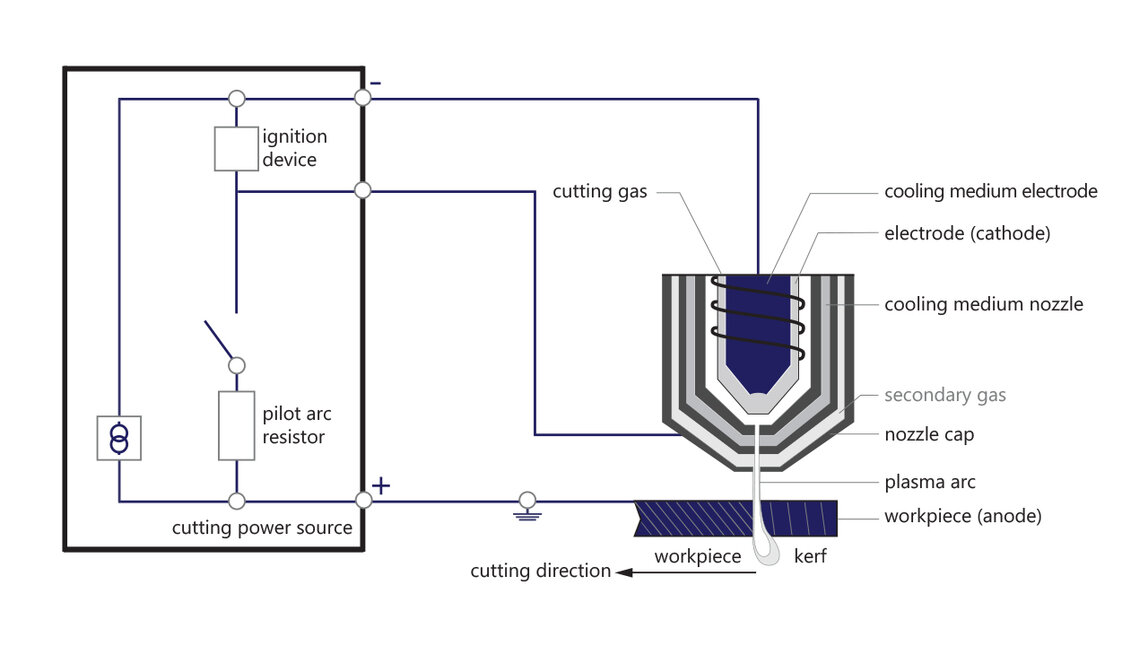

A plasma cutter generates an arc between an electrode and the workpiece. The plasma arc melts the metal and the plasma gas removes the melted materials.

Most efficient cuts with plasma cutting

With plasma technology, all conductive materials such as mild steel, stainless steel and aluminium in the medium material thickness range can be processed. Advantages of modern plasma systems are high quality cutting results, high cutting speeds, only a small heat-affected zone and the unbeatable cost-benefit ratio compared to other cutting technologies. Plasma cutting is systematically one of the thermal cutting processes. It was originally developed for cutting metals that cannot be separated by flame cutting due to their chemical composition, such as aluminium or copper and their alloys, high-alloy steels, but also hard metals. In the industrial sector, plasma cutting systems are also indispensable when it comes to mild steel due to their numerous advantages over alternative cutting processes.

Advantages of plasma cutting

- High cutting speeds

- High-quality cutting results

- Low cutting meter costs

- Cutting of all electrically conductive materials

- Versatile

CNC plasma cutting systems convince with economical and precise cuts and are unrivalled, especially for medium material thicknesses. Modern plasma cutting machines combine efficiency, lasting performance and multifunctionality.

Plasma technology

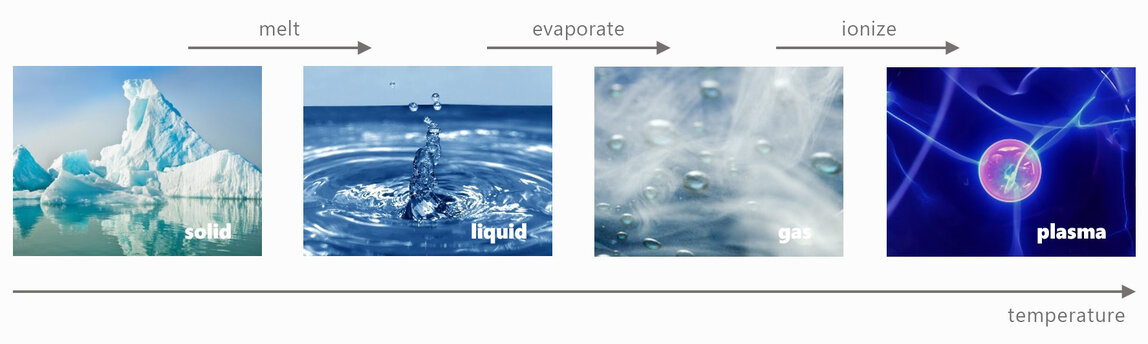

A plasma cutter generates an arc between an electrode and the workpiece. Plasma is also called the fourth state of aggregation. It is generated by ionising electrically conductive gas through an energy supply (high voltage). Due to the high energy density of the resulting arc, which reaches up to 30,000 degrees Kelvin, the metal melts and is blown out by a gas jet, creating the kerf.

A plasma cutter generates an arc between an electrode and the workpiece. Plasma is also called the fourth state of aggregation. It is generated by ionising electrically conductive gas through an energy supply (high voltage). Due to the high energy density of the resulting arc, which reaches up to 30,000 degrees Kelvin, the metal melts and is blown out by a gas jet, creating the kerf.

The cutting process is performed by a so-called pilot arc, which is ignited by feeding an ignition gas between the electrode and the nozzle with high frequency voltage (non-transferable arc). This relatively low-energy pilot arc ionizes the distance between electrode and anode (workpiece). The plasma gas is switched on as soon as the pilot arc makes contact with the workpiece. This creates the main arc while automatically increasing the current (transferring arc). The material is melted by the thermal energy of the arc and driven out of the kerf by the kinetic energy of the cutting gas.

The material to be cut must be electrically conductive for plasma cutting, as the workpiece is part of the circuit (anode). The grounding should therefore be as consistent as possible. And so that optimum cutting results can always be achieved, the type of consumables and plasma gases change depending on the material.

Electrode and plasma nozzle are exposed to high currents and thus high strains during plasma cutting – these are therefore components with a limited lifetime. The service life of the electrode is largely determined by the level of the cutting current, the number of ignitions and the type of plasma gas. In addition, the gas and current management at the start and end of the cut as well as the heat dissipation from the electrode play a decisive role. Essential influencing factors of the nozzle service life are:

- Nozzle diameter, mass and thermal conductivity

- Power used (current x voltage)

- Duty cycle of the arc

- Number of ignitions

- Hole punching procedure

- Optimum distance from torch to workpiece (intelligent height control)

- Purity of cutting and swirl gases: the gas air must be dry and free of oil and grease

- Intensity of cooling

- Use of certified original consumables

Manual or automated plasma cutting

A distinction is made between manual plasma cutting or automated plasma cutting with a CNC machine or robot.

Hand plasma cutters (also known as manual plasma cutters) are mainly used where precision, accuracy and reproducibility are less important than a quick separating cut. Manual plasma cutters are therefore not only used in the metal processing industry, but for example, the mobile version of the plasma cutter is often used for rescue work by the Federal Agency for Technical Relief (THW) or fire departments.

Plasma cutting machines are most frequently used in the metalworking industry. They score points in the CNC-guided 2D cutting range for thin and medium sheet thicknesses with very good cutting quality and very high cutting speeds at comparatively low cutting meter costs. Thanks to sophisticated rotating units for bevel cutting, modern CNC machines also show their strength in 3D processing: nowadays, nothing stands in the way of extremely precise weld edge preparation with bevel angles of up to 50°.

With optional additions, modern cutting systems can be used not only for processing sheet metal, but also, for example, for processing pipes, profiles and domes. Multifunctional plasma cutting machines also offer further options for processing materials: The systems can be equipped with modules to enable drilling, countersinking, tapping, marking, punching and labelling. In addition, plasma technology can be combined with oxyfuel cutting respectively flame cutting, with laser cutting or with waterjet cutting.

Robot cutting systems

Robots are still widely regarded as indispensable when it comes to preparing subsequent welding seams on already cut components. However, there is now an incomparably more efficient alternative that makes a huge difference to this supposed certainty: The new process is called ABP® – Additional Beveling Process – and enables extremely precise subsequent beveling on gantry cutting systems.

Cutting range

The typical cutting range in modern plasma cutting is between 1 mm and 50 mm – here, very good quality and economically extremely efficient cutting results are achieved. For higher material thicknesses, CNC cutting systems with plasma gas are usually combined with technologies for flame cutting. The following materials among others are usually processed with plasma cutting technology: mild steel (fine-grained steel, Hardox), stainless steel (V2A), chrome-nickel steel (V4A), aluminium, copper, brass, titanium, armour steel.

Where is plasma cutting used?

Cutting with plasma is applied in the most diverse industries: For example, plasma cutting systems are used in metal cutting (contract cutting or contract manufacturing), in mechanical engineering, plant and container construction, shipbuilding, ventilation construction, pipeline construction, prototype construction or vehicle construction. In other words, in all those branches of industry that deal with metal processing and cutting processes.

.jpg)

What is a CNC plasma cutter?

Plasma technology can be used to efficiently process all conductive materials such as mild steel, stainless steel and aluminum in the medium material thickness range. A CNC plasma cutting machine – also called a plasma torch – is a precise CNC-controlled tool with which metals and various geometries (including sheet metal, pipes, beams, domes) can be cut.

How does a plasma cutter work?

A plasma cutter generates an arc between an electrode and the workpiece. Plasma is an electrically conductive gas with a temperature of about 30,000 °C. Due to the high energy density of the arc, the metal melts and is blown out by a gas jet, creating a kerf.

What is plasma?

Plasma is an electrically conductive gas with a temperature of about 30,000 °C. It is also known as the fourth state of aggregation.

What do I need for plasma cutting?

In order to cut metals and various bodies using plasma technology, the following components are necessary: a plasma source (or plasma power source: major manufacturers are Kjellberg and Hypertherm), a cutting head, electricity and the appropriate cutting gas.

What kind of gas do I use for plasma cutting?

For simple plasma cutting, air is sufficient. For the more precise fine plasma cutting, oxygen is usually recommended as the cutting gas for mild steel and air as the swirl gas (for constricting the arc). Stainless steel and aluminum are mainly cut with nitrogen, forming gas or argon/hydrogen. The exact composition of the gas mixture depends on the material thickness to be processed.

What are the advantages of plasma cutting compared to laser cutting?

With plasma, even medium material thicknesses up to 50 mm can be cut with good quality and economic efficiency. Plasma cutting has lower requirements for the material to be processed and its surface. In addition, the acquisition costs of a plasma cutting system are significantly lower than the investment in a laser cutting system.

What is the difference between plasma cutting and oxyfuel cutting?

Plasma can cut all metallic conductive materials, oxyfuel (also called autogenous flame cutting) only unalloyed or low-alloyed steels. In addition, plasma is faster and more flexible in the thin to medium sheet thickness range, as well as qualitatively better especially in the thin sheet thickness range.

What are the advantages and disadvantages of plasma cutting?

Advantages and strengths of plasma technology:

- Highest flexibility for cutting all electrically conductive materials

- Lowest demands on material characteristics and working environment

- High cutting speeds and good quality in the thin and medium sheet thickness range

- Cutting of high-strength structural steels with low heat input

- Very good automation capability

- Underwater plasma cutting for very low heat distortion of the workpieces and low noise level in the working environment

Disadvantages and limitations of the technology plasma:

- Wide kerf compared to laser cutting and waterjet cutting

- Fine contours with loss of quality

- Relatively high sound level

Which geometries and contours can be cut with plasma cutting?

In general, the geometry of the contour depends on the respective processing machine. While only sheet metal can be processed with flatbed gantry systems, robots or multi-axis units are also capable of processing 3D bodies such as pipes, profiles or domes. However, for a component size below about 10 mm, other cutting processes are typically used (laser, waterjet).

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization