What does laser cutting cost?

You are interested in laser cutting or would like to purchase a laser cutting machine? Then you are at the right address with the company MicroStep! For the production of our laser cutting machines we can draw on 30 years of expertise. Our laser cutting systems are highly efficient quality machines that are manufactured specifically for you and your individual requirements. Customer care and service are our top priority!

Lasercutting saves time and money!

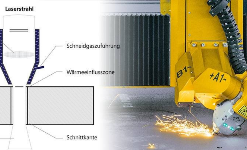

In the thinner sheet metal range up to 10 mm material thickness, laser cutting technology is by far the fastest process. In addition, it is one of the most precise applications in metal processing. MicroStep's laser cutting machines are equipped with fiber laser technology, which is up to 5x more energy efficient than the older CO2 technology!

Tip: There are various subsidy programs that promote the purchase of energy-saving laser cutting machines! It is definitely well worth recalculating your energy consumption for laser cutting. We will be happy to advise you on whether you can take advantage of one of the subsidy programs.

Why laser cutting is profitable for you!

As a company in the metal industry, you have the option to purchase the laser cuts or make them yourself. Before you decide to buy a laser cutting machine, you should check how high your annual costs for the purchase of the cut parts are. If the costs of the laser cuts amount to approx. 50.000–60.000 Euro, it is already worthwhile for you to analyze the acquisition of a laser cutting machine. Because as a company you have the possibility to write off the investment for a laser cutting machine over 6–7 years.

Another advantage of a purchase is the time flexibility! You have the possibility to produce smaller quantities and long delivery times are completely eliminated. This ensures a very high flexibility in order planning.

Please arrange a telephone consultation appointment with our customer service! We will be happy to advise you in detail about the costs and individual advantages of laser cutting based on your individual production needs.

Your advantages at a glance:

- 30 years of expertise in the manufacturing of cutting systems

- European manufacturing

- Special machine construction & standard machine construction

- Software & control from one source

- Fiber laser technology

- Practical user training

- Close-knit service & support network

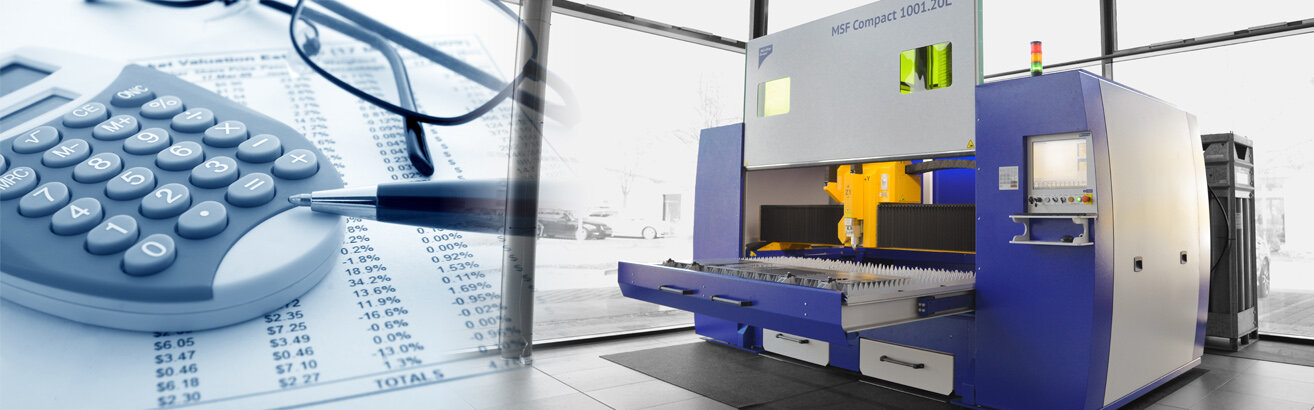

How much is the purchase price of a laser cutting machine?

Laser cutting machines are available from MicroStep in a wide range of price classes. The price depends on the one hand on which performance the machine is to be equipped with and on the other hand which equipment is desired by the customer. The laser cutting machines from MicroStep start at a price of approx. 200,000 Euro and are delivered ready for operation. The basic configuration includes the guiding machine, laser source, suction system and all services and training for the machine. We can configure our laser cutting machines according to customer requirements and, for example, implement automated processes or the connectivity to a material storage system. The machine software as well as the control system can also be individualized.

How much does the machine hour of a laser cutting machine cost?

The calculation of the machine hour of a laser cutting machine is usually based on the rate that a machine costs in an operational state at every hour (24/7) without being actively used. The following parameters are included in the calculation:

- What was the purchase price of the machine?

- How much is the amortization and how long is the amortization period?

- What is the cost of electricity for the ready-to-use condition?

What are the fixed costs such as the cost of insurance or maintenance or the space costs broken down.

How do I calculate the laser cutting?

Laser cutting is calculated in two simple steps:

- What does the cutting cost me per hour: material costs (material type, material thickness), machine cost hours, machine operator wages, gas consumption, electricity consumption, wear part consumption all play a role here.

- Total time required for laser cutting: preparation (setting the machine), post-processing (removal of parts, commissioning, shipping, etc.).

According to our experience, we can say that the machine hourly rate starts from about 50 Euro per hour, depending on the wage of the machine operator. You want to calculate your individual hourly rate? We will provide you with all the necessary information and tools for your machine that you need for the calculation.

What are the costs for laser cutting?

In addition to the purchase price, laser cutting also involves running costs that should be kept in mind when calculating the costs: Hourly wage of the machine operator, gas consumption, electricity consumption, consumption of wear parts and maintenance costs. The maintenance costs for a single-shift operation are usually calculated at approx. 2% of the machine purchase value per year. If the laser cutting machine runs around the clock in shift operation, the maintenance costs are correspondingly higher. The additional costs in shift operation depend individually on the operating hours. Our machine experts at MicroStep will be happy to advise you on the maintenance contracts that are right for you.

Why is laser cutting less expensive compared to other processes?

At first glance, laser cutting doesn't really seem cheaper compared to other processes. However, if you take a closer look, you can save yourself money in the long run:

Laser cutting is very effective and time-saving - and time is money!Laser cutting technology has proven itself for many years and continues to develop rapidly. Next to waterjet cutting, it delivers the most precise cutting quality. This means that hardly any reworking of the cut parts is required. In addition, laser cutting in the thin to medium sheet thickness range ensures a very high cutting speed.

How much power does a laser cutting machine need?

Compared to plasma or waterjet cutting, laser cutting consumes less power. How much power is consumed in the end depends on the strength of the laser source.

Example: a 2 kW laser source needs about 5 kW power. For a 12 kW laser source, you need to calculate about 30 kW of power (if the respective laser source operates at maximum laser power).

The power consumption of the laser source is therefore variable and depends largely on the thickness of the material to be cut.

The respective power consumption of the laser system therefore depends on:

- the size of the system and

- the laser power of the laser source used in the cutting process

The dimension of the extraction system also plays a role here. In modern systems, only individual segments are extracted in the cutting area to save energy. Depending on the installation situation, the design of the machine and positioning, as well as the length of the pipelines, power consumption is also a factor here.

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization