eB ULTRA series

ultra-efficient, ultra-fast, ultra-precise

The eB ULTRA press brake | The perfect start

The 100% electric press brake of the eB ULTRA series from MicroStep Europa and our technology partner ACCURL is economical to purchase and works accurately and reliably. Even the basic version of the series has movable support arms and pneumatically operated quality tool clamps, type PROMECAM. In addition, material handling to and from the system can be automated in conjunction with a robot.

Features

eB ULTRA: The ideal introduction to high-quality bending

The eB ULTRA series from MicroStep Industry can be equipped with a press force of 250 to 1,250 kN, depending on requirements...

State-of-the-art control technology from the quality manufacturer Delem

The standard version of the series is equipped with the latest CNC control technology from the renowned manufacturer Delem: The...

High flexibility: backgauge with up to 6 axes

The backgauge of this series already includes four CNC-controlled axes as standard: X, R, Z1, Z2. This ensures a very high...

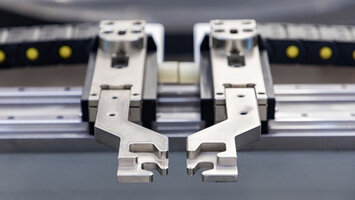

Quality tool clamping systems

MicroStep Industry press brakes are equipped with high-quality clamping systems from ACCURL® as standard. The upper tool...

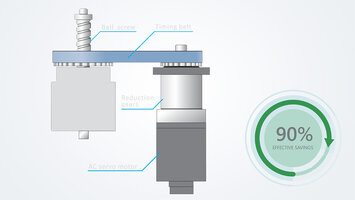

Sustainable, efficient and fast: all-electric drive

The eB ULTRA is an all-electric system series that is technically equipped to the highest level and impresses with its ease of...

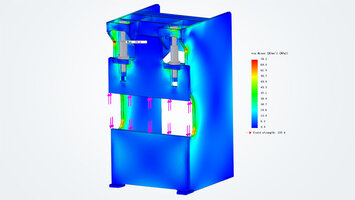

Top-level mechanical engineering thanks to 3D CAD modeling techniques

Thanks to modern 3D CAD design with integrated analysis tools, potential stresses and deformations can be virtually detected...

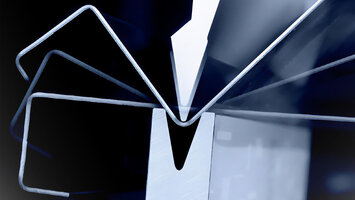

Precision: Constant bending angle over the entire length

The ultra-precise all-electric drive system of the eB ULTRA series in combination with the Accurl Master® crowning system...

Integrated tool store

Particularly practical: A tool store is already integrated into the side panel of the new eB ULTRA press brake, which means...

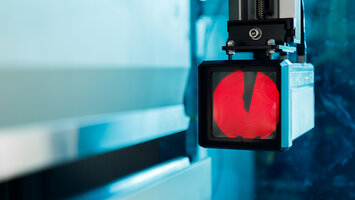

Highly dynamic safety equipment

Maximum safety with minimum loss of time: The bending machines are equipped with a visible laser barrier. This IRIS safety...

Remote Diagnostics

Thanks to powerful remote maintenance solutions, MicroStep Europe provides fast and efficient support via remote access. Most...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

| Length | 1,550 to 4,090 mm |

| Width (= Depth) | 1,350 to 1,950 mm |

| Height | 2,150 to 2,850 mm |

| Pressing force | 250 to 1,250 kN |

| Bending length | 800 to 3,050 mm |

| Standard stroke (= Hub) | 150 to 270 mm |

| Installation height | 380 to 515 mm |

| Table width | 90 mm |

| Rapid speed | 180 to 220 mm/s |

| Working speed | 0 to 10 mm/s |

| Return speed | 200 to 230 mm/s |

| Motor power | 8 to 44 kW |

| X-axis travel | 350 to 600 mm |

| X-axis speed | 1,000 mm/s |

| R-axis travel | 160 mm |

| Z-axis speed | 1,500 mm/s |

| Oil filling | Fully electric drive, oil only required for lubrication |

| Weight | 2,850 to 9,650 kg |

Control

Control technology from Delem

Control technology: Only the finest

The standard version of the eB ULTRA series is equipped with the latest CNC control technology from the renowned manufacturer Delem: The new generation of DA-Touch controls offers a very high degree of efficiency in the programming, operation and control of press brakes. Convenient operation combined with state-of-the-art technology ensures maximum productivity.

The touchscreen enables access to the proven Delem user interface and also direct navigation between programming and production. Functions are located directly where they are needed, with optimized ergonomics throughout the application. DA-Touch series controllers offer either 2D or 3D programming, depending on the option selected, which includes automatic calculation of the bending sequence and collision detection.

The overall 3D machine setup includes multiple tool stations and provides instant feedback on product feasibility and handling. Highly efficient control algorithms optimize the machine cycle and reduce the time required for set-up. This makes the use of press brakes easier, more efficient and more versatile than ever.

Alternatively, control systems from the manufacturer ESA are also available.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization