MSE SmartFL

Faser laser cutting 4.0:

powerful, reliable, economical

The MSE SmartFL | Laser cutting at top level

The MSE SmartFL fiber laser cutting machine from MicroStep Europa and our technology partner ACCURL is a powerful system for high-quality 2D laser cutting. The series is available in cutting areas from 1,500 x 3,000 up to 2,500 x 12,000 mm and can be equipped with laser sources of up to 60 kW.

The system owes its high reliability and process safety to the fact that it is equipped entirely with top-quality brand-name components. At the same time, the highly attractive pricing with comparatively manageable investment and operating costs enables a fast return on investment. And, of course, all this comes in a package with MicroStep‘s outstanding premium service!

The MSE SmartFL is more than a modern laser cutting system with high-quality components: The system is already well equipped for the manufacturing of the future! As theMSE SmartFL is optimized for the use of IndustryFusion, a cross-vendor open source connectivity solution for Smart Factories and Smart Products.

Features

MSE SmartFL: High-quality 2D laser cutting

The MSE SmartFL is a powerful, reliable and extremely economical fiber laser cutting system from MicroStep Europa.

Highly dynamic machine gantry and solid, durable frame construction

A cast aluminum gantry guarantees higher stiffnesses with a simultaneous weight reduction compared to similar steel gantries.

High power: up to 60 kW laser power for maximum productivity

More laser, more beam force, more power: laser sources with an output of up to 60 kW are available for this series.

Top-quality brand-name components

The system owes its high reliability and process safety to the fact that it is equipped entirely with top-quality brand-name .....

Automatic shuttle table with sectional suction system

The shuttle table system consists of two movable cutting tables. These tables change position between ...

High efficiency in spite of strong performance

Highly attractive pricing with comparatively manageable investment and operating costs enables a fast return on investment ...

Innovative filter technology

Extraction and filter systems are used wherever metals are processed thermally or mechanically and smoke or dust is generated...

Green SmartFactory 4.0: Ready for Industry 4.0

The machine is more than just an optimal entry into high-quality laser cutting: The series is prepared for the use of...

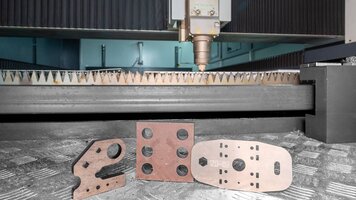

Excellent cutting quality on different materials

Thanks to best components, the MSE SmartFL achieves excellent cutting quality on most different workpieces.

Remote Diagnostics

With the control system MSE SmartControl and the extensive remote maintenance modules, MicroStep Europa offers the best ...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

|

|||||||||||

| Effective length of work area |

3,000 to 12,000 mm |

||||||||||

| Effective width of work area |

1,500 to 2,500 mm |

||||||||||

|

Automatic shuttle table |

included as standard | ||||||||||

Various series models at a glance |

|||||||||||

| Model | MSE SmartFL 3001.15 |

MSE SmartFL 4001.20 |

MSE SmartFL 6001.20 |

MSE SmartFL 6001.25 |

MSE SmartFL 8001.25 |

MSE SmartFL 12001.25 |

|||||

| Max. permissible workpiece weight (kg)* | 3,000 | 3,500 | 4,000 | 5,000 | 6,000 | 12,000 | |||||

| Work area | Length (mm) | 3,010 | 4,010 | 6,010 | 6,010 | 8,010 | 12,010 | ||||

| Width (mm) | 1,505 | 2,010 | 2,010 | 2,510 | 2,510 | 2,510 | |||||

| Dimensions incl. peripherals** |

Length (mm) | 10,600 | 12,500 | 17,000 | 17,000 | 21,500 | 30,000 | ||||

| Width (mm) | 4,500 | 5,500 | 5,500 | 6,000 | 6,000 | 6,000 | |||||

| Height (mm) | 2,700 | 2,700 | 2,700 | 2,700 | 2,700 | 2,700 | |||||

| *For laser power exceeding 8 kW, an enhanced version of the cutting table must be integrated, allowing for a higher maximum workpiece weight. **Approximate figure including space required for peripherals (laser source, filter system, cooler, safety equipment). |

|||||||||||

Tools |

|||||||||||

| Possible number of tools | 1 | ||||||||||

| Possible cutting processes | fiber laser | ||||||||||

| Maximum material thickness | according to laser source upt to maximally 60 kW | ||||||||||

Precision |

|||||||||||

| Traverse speed | up to 180,000 mm/min | ||||||||||

| Positioning accuracy Pa | ± 0.03 mm according to VDI/DGQ 3441 | ||||||||||

| Repeatability Ps | ± 0.05 mm according to VDI/DGQ 3441 | ||||||||||

| X, Y axis | linear guides, driven on both sides and helical toothed racks | ||||||||||

| Z axis | rack | ||||||||||

| Gantry type |

cast aluminium gantry |

||||||||||

Control & Software |

|||||||||||

| Steuerung |

MSE SmartControl |

||||||||||

| Main control panel |

ergonomic 2 x 21.5“ TFT Multitouch panel |

||||||||||

| Operating system |

Windows 10TM IoT Enterprise |

||||||||||

Available laser source power | Maximum sheet thickness |

|||||||||

| Power | Mild steel (MS) | Stainless steel (SS) | Aluminium (Al) | Brass (Br) | Copper (Cu) | ||||

| 2 kW | 12 mm | 6 mm | 8 mm | 4 mm | 3 mm | ||||

| 3 kW | 18 mm | 10 mm | 12 mm | 6 mm | 5 mm | ||||

| 4 kW | 20 mm | 12 mm | 15 mm | 8 mm | 8 mm | ||||

| 6 kW | 25 mm | 20 mm | 20 mm | 15 mm | 10 mm | ||||

| 8 kW | 25 mm | 25 mm | 25 mm | 15 mm | 12 mm | ||||

| 10 kW | 25 mm | 30 mm | 30 mm | 15 mm | 12 mm | ||||

| 12 kW | 30 mm | 30 mm | 30 mm | 20 mm | 15 mm | ||||

| 15 kW | 35 mm | 35 mm | 35 mm | 20 mm | 15 mm | ||||

| 20 kW | 40 mm | 40 mm | 40 mm | 25 mm | 15 mm | ||||

| 30 kW | 50 mm | 40 mm | 40 mm | 25 mm | 15 mm | ||||

|

|

|||||||||

| All specifications subject to change | |||||||||

Software

Software from MicroStep® – developed especially for cutting

To allow you to concentrate fully on your production, our MicroStep® software solutions, drawings and cutting plans help you to intuitively convert them into finished components. Part of our product range also includes automation solutions for the organization of your entire cutting process.

Asper Basic

Asper Basic is the ideal tool for an easy and fast creation of NC programs for different cutting technologies (plasma, oxyfuel, laser or waterjet).

Control

Fast and highly dynamic: the machine control MSE SmartControl

With the MSE SmartFL, a modern, intuitive user interface guarantees that cutting plans can be converted reliably and highly effectively into finished components. The MSE SmartControl meets all the requirements placed on modern, high-performance control systems today.

MSE SmartControl machine control

Operation via a dual panel (2 x 21.5" touchscreen) as well as an additional handheld device

Together with the German control specialist Eckelmann, MicroStep Europa has developed the MSE SmartControl control system. The machine control, manufactured for operation under all environmental conditions, is used to control the cutting components as well as the cutting peripherals. The MSE SmartControl features a user-friendly HMI (Human Machine Interface), which can be conveniently operated via two 21.5" touchscreens as well as via an additional handheld device. A clear and easy-to-use graphical user interface allows quick familiarization. The machine control system includes an industrial PC. The control components are located in a control cabinet. The cables are routed in a slip-proof cable duct. In addition to fast height control for a constant distance to the workpiece, the control system also offers CNC-controlled compensation mechanisms for optimum laser focus position. Other functions such as sheet position detection, kerf compensation or wear part monitoring are integrated in the control as standard.

The MSE SmartControl is also optimized for the use of IndustryFusion, a vendor-independent open source networking solution for smart factories and smart products.

Further information: www.industry-fusion.com

Media

MSE Smartᶠᴸ: 2D-Laserschneiden auf Top-Niveau

Video: The MSE SmartFL in customer use

2D cutting

Cutting system

Material handling

Control system

Cutting samples

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization