Flame cutting | Info on oxyfuel technology

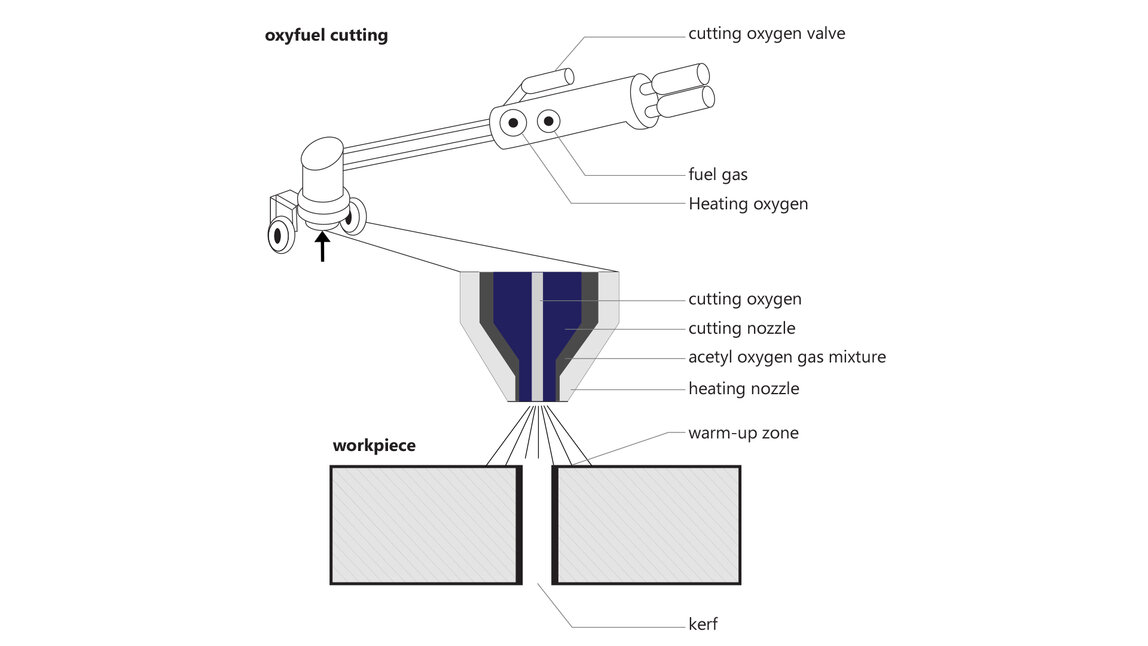

Flame cutting, also known as oxyfuel cutting, is one of the oldest cutting processes in metal processing. With the help of a fuel-oxygen mixture the metal combusts and is blown out of the kerf. The principle of thermal cutting stands behind flame cutting and is mainly used for thick materials.

Flame cutting history

The oxyfuel technology invented as early as 1901 – also known as oxyfuel flame cutting – is one of the oldest, yet most important cutting processes in the metalworking industry. In this principle of thermal cutting of steel, the metal, previously heated to ignition temperature, is oxidized with an oxygen jet and blown out of the kerf. In all industries in which low-alloy steels with a material thickness of 20 mm or more have to be cut precisely and quickly, oxyfuel technology proves to be perfectly suited and particularly economical. Especially in heavy industry, this method is indispensable – despite the increasing importance of other processes (plasma cutting, laser cutting, waterjet cutting) – as there are no economical alternative cutting options for larger material thicknesses from 50 mm upwards. The development of the oxyfuel rotator also opens up new possibilities from which users can benefit enormously.

Advantages of oxyfuel cutting

- High-quality cutting results

- Economical cuts

- Processing of material thicknesses of up to 300 mm

- Versatile

Flame cutting machines convince by their robust construction, precision and performance with large material thicknesses.

What are the advantages of oxyfuel cutting compared to other cutting methods?

Compared to other thermal cutting processes, oxy-fuel cutting is particularly impressive when it comes to processing large material thicknesses. It is particularly suitable for cutting from 40 mm up to several hundred millimetres - a field of application in which laser and plasma systems often reach their limits. However, this technology also offers advantages for smaller material thicknesses - for example in terms of angular accuracy for small internal contours, especially in combination with plasma technology. The robust technology is specially designed for continuous operation and is predestined for demanding industrial applications such as steel construction or shipbuilding. Thanks to the long service life of the systems and the low maintenance requirements, oxyfuel flame cutting is an economical, reliable and proven solution for numerous cutting tasks.

Oxyfuel technology

The flame cutting aggregate consists of a ring-shaped heating nozzle, a separate fuel gas-oxygen supply and an oxygen cutting nozzle placed in the middle.

With a heating flame, the material is heated locally to the individual ignition temperature and prepared for the cutting process. The heating flame is created by feeding a fuel-oxygen mixture into the heating nozzle. The oxygen escaping under high pressure (with a purity of at least 99.5 percent) oxidizes the carbon-containing metal and burns a kerf into the material.

The carbon content of the workpieces must be taken into account here: a high carbon content increases the ignition temperature and simultaneously reduces the melting temperature. Workpieces to be processed by flame cutting must always have a lower ignition temperature than their melting temperature. Metals with a carbon content below 0.3 % can be cut without any problems. For materials with a carbon content between 0.3 % and 1.6 %, the area to be cut should be preheated or even reheated in order to minimize or completely avoid cracks and stresses in the workpiece. However, the processability of a material using oxyfuel technology also depends on the composition of the alloys. Thus, other elements such as chromium and nickel influence the flame-cuttability.

Manual or automated flame cutting

In the field of oxyfuel flame cutting, manual cutting torches and machine cutting torches can be distinguished from each other. Depending on requirements, material and industry, there are numerous possibilities for oxyfuel technology.

Manual oxyfuel cutting – also known as hand cutting torch, flame cutter or flame-cuting saw – is mainly used on construction sites, in workshops and in the basic equipment of rescue units, such as the Federal Agency for Technical Relief (THW) and the fire departments. In these applications it is not the precision and reproducibility of components that is important, but the flexible and fast processing of large material thicknesses of relatively small workpieces. However, fire hazard and workpiece distortion due to thermal influence greatly limit the application possibilities for manual flame cutting here.

Automated CNC oxyfuel cutting systems have become indispensable, especially in precision-oriented metal construction. The CNC machines are sometimes equipped with more than just one oxyfuel torch for efficient parallel cutting operations and can usually be combined with various components such as plasma cutting units and pipe cutting devices. The precision and high automation degree of the cutting machines make working with metal easy and efficient. They therefore offer the optimum solution for almost all material thicknesses and score with functionality and flexibility.

Cutting range

In recent years, oxyfuel technology has undergone considerable improvements where fuel gases and burner heads are concerned, which have a positive effect on cost-effectiveness and cutting quality. The cutting range of oxyfuel technology covers material thicknesses starting from 5 mm, for material thicknesses above 160 mm flame cutting technology is the only possible cutting method within the thermal cutting comparison.

In recent years, oxyfuel technology has undergone considerable improvements where fuel gases and burner heads are concerned, which have a positive effect on cost-effectiveness and cutting quality. The cutting range of oxyfuel technology covers material thicknesses starting from 5 mm, for material thicknesses above 160 mm flame cutting technology is the only possible cutting method within the thermal cutting comparison.

The limit of oxyfuel cutting is drawn by the chemical composition of the material: If the carbon content of the material is less than 0.3 %, flame cutting is possible without problems, between 0.3 % and 1.6 %, preheating of the area to be cut is necessary. If the carbon content exceeds 1.6 %, the component is no longer suitable for oxyfuel flame cutting.

The quality of the flame cut is influenced by various parameters. The choice of fuel gas – usually a propane-oxygen or acetylene-oxygen mixture – and the resulting flame temperature are decisive for the cutting speed. Higher flame temperatures mean that the optimum ignition temperature is reached more quickly. The acetylene-oxygen mixture reaches flame maximum temperatures of 3160 °C and ensures maximum cutting speed and lower cutting costs. But also high oxygen pressure and an optimum distance between nozzle and workpiece contribute to good cutting results in oxyfuel technology.

Where is flame cutting used?

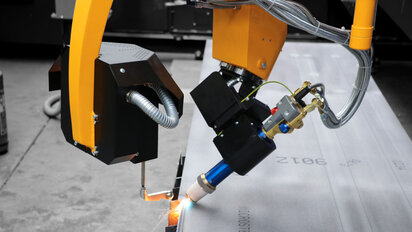

The application range of oxyfuel technology is diverse. It can be found in all industries that specialize in the processing of steel in the high material thickness range. It is therefore impossible to imagine shipyards, steel construction, plant engineering and mechanical engineering without it. But also in the basic equipment of the Federal Agency for Technical Relief (THW) and the fire department, on building sites, in junkyards and in workshops, hand cutting torches with oxyfuel technology are used; wherever an efficient and flexible cutting process of metals is required. Modern oxyfuel cutting solutions can be combined on a CNC machine with a variety of other equipment options for processing sheet metal, pipes and profiles: for example, for plasma cutting, drilling, tapping, countersinking or marking. Special solutions with flame cutting technology are also used successfully: for instance, a plasma cutting system for sheet metal processing with an additional robot arm including oxyfuel technology for 3D processing of large pipe formats with higher wall thicknesses.

The application range of oxyfuel technology is diverse. It can be found in all industries that specialize in the processing of steel in the high material thickness range. It is therefore impossible to imagine shipyards, steel construction, plant engineering and mechanical engineering without it. But also in the basic equipment of the Federal Agency for Technical Relief (THW) and the fire department, on building sites, in junkyards and in workshops, hand cutting torches with oxyfuel technology are used; wherever an efficient and flexible cutting process of metals is required. Modern oxyfuel cutting solutions can be combined on a CNC machine with a variety of other equipment options for processing sheet metal, pipes and profiles: for example, for plasma cutting, drilling, tapping, countersinking or marking. Special solutions with flame cutting technology are also used successfully: for instance, a plasma cutting system for sheet metal processing with an additional robot arm including oxyfuel technology for 3D processing of large pipe formats with higher wall thicknesses.

The oxyfuel rotator creates completely new possibilities: Compared to the triple torch unit, completely new geometries can be cut, for example for the weld seam preparation. Simple V cuts as well as complex X, Y or K cuts are possible on a wide range of sheet thicknesses. Compared to robot solutions, the system also impresses with significantly lower investment costs. Production sites all over the world benefit from the endless rotating bevel unit with oxyfuel technology every day.

What developments are there in the automation of oxyfuel flame cutting?

The automation of oxyfuel flame cutting has made significant progress in recent years. Modern CNC-controlled oxyfuel flame cutting systems enable high-precision and reproducible processing of even complex geometries. By using a 3D bevel cutting unit, automated weld seam preparation can also be realized along non-linear contours. Intelligent control systems automatically adjust relevant process parameters such as cutting speed, gas flow and torch position. In addition, automatic height controls ensure a constant distance between the torch and the workpiece, which improves cutting quality and reduces wear. Slag discharge devices also minimize manual intervention and speed up the overall process. These developments not only make oxy-fuel flame cutting more efficient and economical, but also future-proof in highly automated production processes.

How does flame cutting work?

In this type of thermal steel cutting process, also known as oxyfuel cutting, the metal, previously heated to ignition temperature, is oxidized with a jet of oxygen gas and blown out of the kerf. This partially burns the material, which is why this process is also known as flame cutting.

What is the difference between oxyfuel flame cutting and plasma cutting?

In oxyfuel cutting, the cutting flame is created only by igniting the outflowing fuel gas and oxygen, whereas in plasma cutting the outflowing gas (plasma gas) is ignited and ionized. In the thin and medium sheet thickness range, this enables plasma cutting to achieve a significantly faster feed rate than oxyfuel cutting. In addition, plasma can be used to cut all metallic conductive materials, whereas oxyfuel is used almost exclusively for unalloyed and low-alloy steels. In the sheet thickness range above 150 mm, however, only oxyfuel cutting is possible. Here, flame cutting is a process without any alternative.

When is oxyfuel cutting considered economically efficient?

Depending on the cutting task (material thickness, batch size, tolerances, subsequent processes, area of application) and whether one has an own cutting system or relies on an external service provider, oxyfuel flame cutting can be economical from as little as 10 mm. In relation to other cutting processes (plasma, laser, waterjet), the efficient range only starts from 20 mm material thickness and also becomes significantly more economical at significantly higher sheet thicknesses.

At what temperature does flame cutting of steel take place?

The melting temperature for flame cutting is about 1500°. The ignition temperature about 20 to 30 percent lower, depending on the carbon content of the material to be cut.

Which material can be used for flame cutting?

Flame cutting is used in particular for unalloyed and low-alloyed metals. For example, for unalloyed mild steels of grade S235JR, S275JR, S355J2. Or for unalloyed pressure vessel steels of grades P265GH or P355GH. Low-alloyed or micro-alloyed steels (both colloquially, officially: thermomechanically rolled fine-grained mild steels) cut by flame-cutting technology are: S355MC, S500MC, S700MC.

How accurate is flame cutting?

An important parameter for accuracy is the guiding machine. Modern flame cutting machines specify accuracies of ± 0.1 - 0.3 mm. This means that with optimum cutting parameters and a clean cutting nozzle, this accuracy can theoretically also be achieved with flame cutting. The most influential factor, however, is the high heat input. Since this causes the material to expand and contract again, dimensional deviations of up to 2 or 3 mm can also occur, depending on the material thickness and part dimensions.

Is oxyfuel cutting an outdated technology?

Flame cutting is one of the oldest cutting technologies. However, it is by no means outdated and is an important and efficient cutting solution in many application areas. In the upper sheet thickness range from 150 mm, this process is almost without any alternative.

What is the maximum thickness achievable with flame cutting?

In the majority of cases, the industry processes materials up to 300 mm thick by machine cutting. But also larger sheet thicknesses up to 1000 mm can be realized with the appropriate technology.

What geometries and contours can be cut with flame cutting?

In general, the geometry of the contour depends on the particular processing machine. While only flat materials can be processed with flatbed systems, for example, there are also systems that enable more advanced processing. For example, robots or aggregates with several axes are also able to process 3D bodies such as pipes, profiles or domes. However, due to the heat generated during this cutting process, a component size of less than about 20 mm is usually not practical.

How is autogenous flame cutting used in the construction industry?

Autogenous flame cutting plays an important role in the construction industry – especially where steel components with high material thicknesses need to be processed precisely and economically. The technology is used, among other things, for cutting solid steel beams, plates, stiffening plates, and connecting elements required for the construction of bridges, halls, high-rise buildings, or other infrastructure structures. Autogenous flame cutting has also proven itself in the manufacture of foundation and machine components such as base plates, brackets, flanges, and support feet. It is used in industries such as shipbuilding and crane construction to process large-format, high-strength sheets and profiles for particularly robust applications.

Is autogenous flame cutting an efficient process?

Autogenous flame cutting is an extremely efficient process, especially when machining thick materials. In this area in particular, it represents an economical alternative to laser or plasma cutting systems. Modern autogenous flame cutting systems are designed for continuous operation, are extremely robust, and can be easily automated. CNC controls, multifunctional extensions, and intelligent software solutions further increase efficiency and enable precise, reliable production even for demanding cutting tasks.

What are the advantages and disadvantages of autogenous flame cutting?

One of the biggest advantages of autogenous flame cutting is the ability to economically process very large material thicknesses – even sheet thicknesses of over 100 millimeters can be cut without any problems. Due to its robust design, autogenous cutting can also be used reliably under difficult conditions. However, the process also has some limitations. It is only suitable for certain materials, primarily unalloyed and low-alloy steels. It is not suitable for stainless steels, aluminum, or other non-ferrous metals. In addition, autogenous cutting produces a relatively wide heat-affected zone, which can lead to material changes and thermal distortion. Other cutting processes are often more suitable, especially for thinner sheets or for fine, precise cuts.

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization