Features

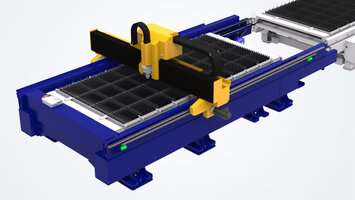

2D laser with robust, dynamic and long-lasting machine design

Gantries with extremely high torsion resistance enable high traverse speedsCompact, manually extractable cutting table for conv...

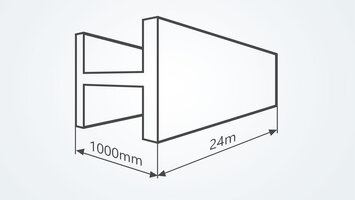

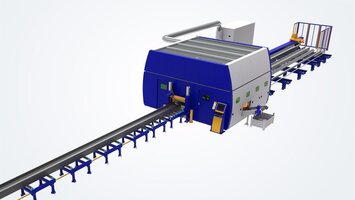

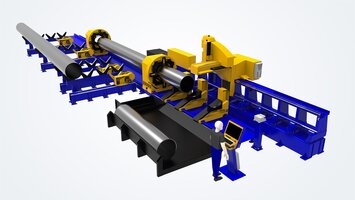

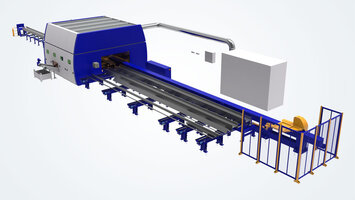

3D processing of beams and profiles up to HEB 1000 and 24 m length

Thanks to its generous work areas, the machine can process beams up to HEB 1000 and a length of 24,000 mm. In addition to the c...

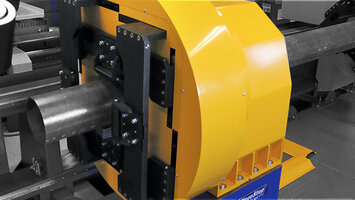

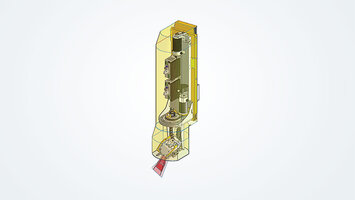

3D pipe & profile processing up to Ø 1,500 mm

Enhance your production range by adding a pipe and profile cutting option for processing of a wide range of pipe diameters incl...

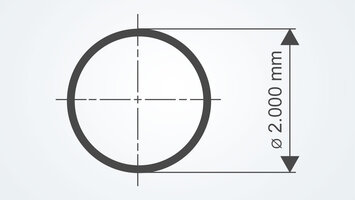

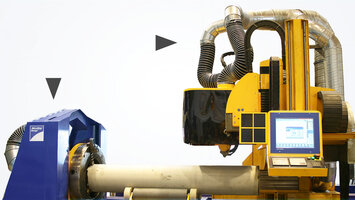

3D pipe and profile cutting up to Ø 2,000 mm

CPCut@s @ PipeCut@s cantilever design with open loading area and a powerful chuck enables clamping and processing of pipes and ...

3D pipe & profile processing up to Ø 1,000 mm

Enhance your production range by adding pipe and profile cutting optionConvenient cutting program creation with MicroStep@s 2D ...

Fume extraction and scrap collection

A fume extraction and scrap collection wagon moves under the gantry between the upper and the lower bed to collect remains from...

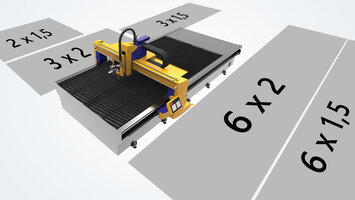

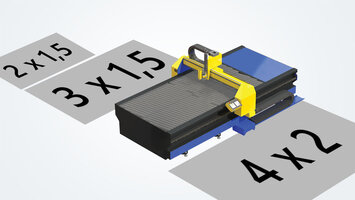

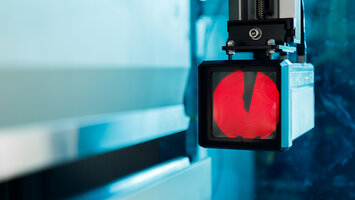

Adaptable: Now in 7 selectable system formats

To adapt the MasterCut Compact cutting package even better to your production, we now offer you the possibility to choose betwe...

Excellent dynamics with positioning speeds of up to 56 m/min.

A rugged machine frame combined with a powerful drive system consisting of digital AC drives, planetary gears and high-precisio...

Unexceptional precision and reproducibility of cut parts

Cutting is the first step in many production processes. Irregularities on the cut part and loss of precision are inevitably tra...

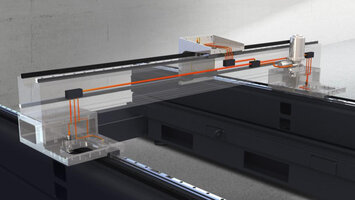

Automatic cutting waste disposal

A conveyor belt transports the small parts that have fallen off the work table or the cutting waste into a separate container t...

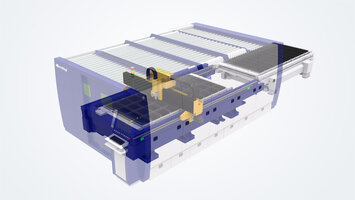

Automated loading and unloading

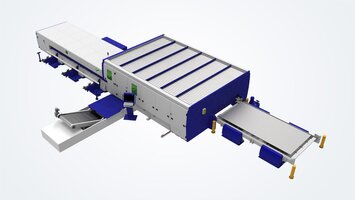

As a time and cost efficient production solution, the DS series features a high degree of automation. The loading of the sheets...

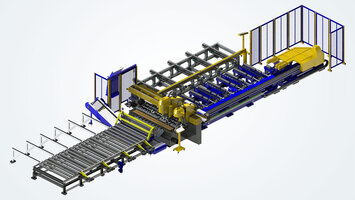

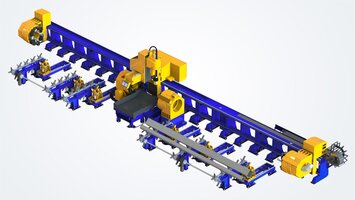

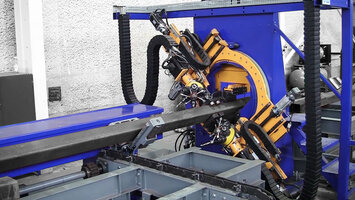

Automated handling of H, U and L beams

Eine ProfileCut wird in Verbindung mit dem MSFeed zur Prozessstraße, um vorrangig H-, U- und L-Träger in unterschiedlichen Größ...

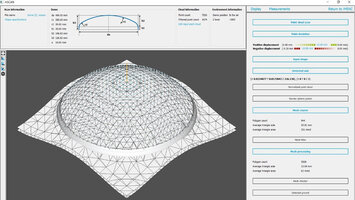

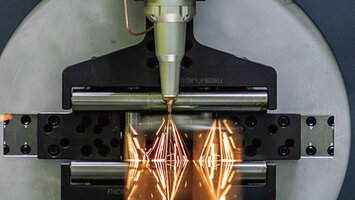

Precise dome processing with mScan

MicroStep@s mScan technology for precise cutting of domes sets new standards in dome processing. A 3D laser scanning process an...

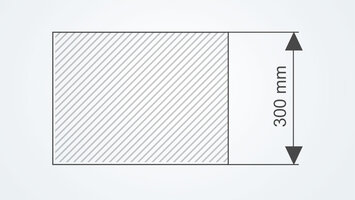

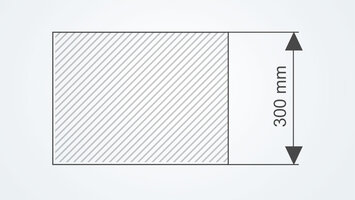

Processing of material thicknesses of up to 300 mm

The consistently well thought-out machine construction with its equipment offers a reliable basis even for high material thickn...

Dome processing up to a diameter of 10,000 mm

This series enables individual and fully automatic dome processing up to 10,000 mm diameter. Depending on the equipment of the ...

Convenient material handling

To fit seamlessly into any production facility, MSLoop does not have to stand on the floor. The embedded version with tables re...

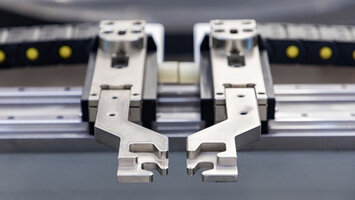

Best mechanical engineering components from renowned manufacturers

Convincing cutting quality can only be achieved by using high-quality components - that is why we use linear guides on all axes...

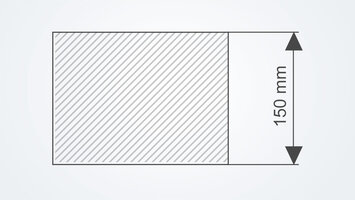

Fine contours and highly precise cuts up to 150 mm

No thermal stress on the cut partCutting of the finest contoursPrecision to the degree of hundredths of a millimeterCutting of ...

The perfect solution for fast and precise cutting

A powerful, compact laser cutting machine for cutting a wide variety of materialsHigh precision and accuracy of parts and conto...

Calibration station with ACTG® unit integrated into the gantry

In case MSF Max is equipped with a laser bevel head, the system comes with the ACTG@ unit and auto-calibration feature by defau...

Convenient loading of profiles

Thanks to the large, open loading area, even heavy beams can be easily and safely slid over the supporting rollers into the wor...

Easy loading and unloading

Thanks to the open machine area with low-positioned guidelines in the longitudinal axis and the mobile cantilever gantry constr...

Sludge removal conveyor

The cutting tank can be optionally equipped with an automatic cleaning system, either with a conveyor belt that carries the slu...

Ergonomic and uncomplicated: The CyberFab® control system

Apart from the externally positioned control console with ergonomic 24@ touch screen display, the system has additional control...

Extremely high reliability even in three-shift production

MicroStep systems are designed for a long machine life @ sometimes even under tough environmental conditions. The resulting ext...

Extremely resistant and robust - even with difficult environmental variables

Extreme conditions are a great challenge for any cutting system. Upon request, MicroStep@ has a suitable solution for all tempe...

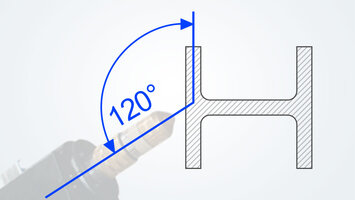

Bevel cutting up to 47° with the plasma bevel head for MasterCut Compact

V- and X-cuts as well as complex Y- or K-cutsFully-automatic compensation of potential mechanical imprecisions of the bevel hea...

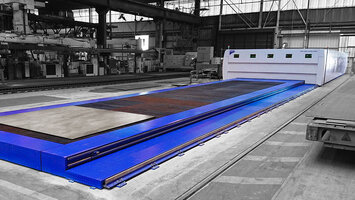

Automated processing of flat materials for steel structures

The DS series offers a variety of automated processing options for flat materials. Besides drilling, 2D and bevel cutting for w...

Flexible means of production for nearly any cutting task

Broad range of processing possibilities @ cutting of plates, pipes @ profiles with plasma or oxyfuel as well as several marking...

Flexible and robust cutting system for almost any cutting task

The systems of this series enable cross-technology work processes (2D and 3D cutting, drilling, countersinking, tapping and mar...

Milling and shaping of fine contours for a variety of materials

• Milling of softer materials like mild metals, plastics, teflon or wood • Suitable for shape machining of flat parts includin...

Extensive automation features and options

Shuttle table with fast table changeover reduces costly downtimesAutomatic focus position and diameter adjustment according to ...

Excellent cutting quality

The compact version of MSF achieves excellent cutting quality on a variety of cut parts thanks to the high-quality of used comp...

Excellent cutting quality

Better cutting quality means less post-processing - components can be processed with much less effort, which can help to save m...

Excellent cutting quality

Better cutting quality means less post-processing, which helps you to save manufacturing costs. A proper technology is availabl...

Heavy-duty fiber laser cutting machine

The MSF Max, with its maximum work length of up to 50,000 mm and width of up to 6,000 mm, is an excellent laser cutting solutio...

Highest precision through the use of high-quality components

The machine maintains an uncompromising quality of components @ linear guidelines in all axes, helical gears, sturdy gantries a...

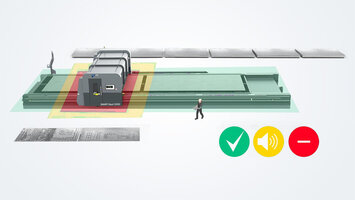

The highest safety standards to protect machine operators

In addition to the already high MicroStep@ safety standards, the system can be extended with the following safety equipment if ...

High-quality components

MicroStep relies exclusively on high-quality components from established manufacturers to ensure long-lasting and accurate resu...

High-quality components

MicroStep uses laser sources from IPG Photonics, the leading manufacturer of high-power fiber laser systems. Sources with a pow...

High dynamics and up to 30,000 mm/min traverse speed

This series allows ideal use of the high cutting speeds in the thin metal sheet range. And thanks to high-quality machine compo...

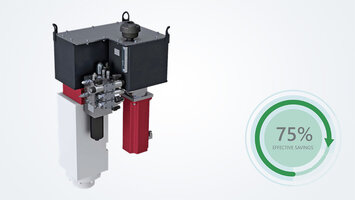

High economic efficiency

2/3 lower power consumption and higher cutting speeds (compared to CO2 laser of the same power)The complete machine is nearly m...

High economic efficiency

2/3 lower power consumption and higher cutting speeds (compared to CO2 laser of the same power)The complete machine is nearly m...

Installed and ready for operation in a short time thanks to easySetup® assembly system

Thanks to the easySetup@ installation concept, the system is installed and ready for operation in a short time. A special carri...

Individual design of the Z-axis stroke up to 1,400 mm

In order to ensure the appropriate flexibility when processing domes, profiles and various higher components, the stroke of the...

Innovative software solutions: Intuitive and easy operation

So that you can fully concentrate on your production, our innovative software solutions help you to intuitively transform drawi...

Extensive configuration possibilities

The ProfileCut is one of MicroStep@s most versatile machines. Besides processing of beams and tubes, the machine can be extende...

Adaptive Bevel Compensation (ABC)

In order to meet the requirements for high precision and/or perpendicularity of the cut parts, MicroStep@s Adaptive Bevel Compe...

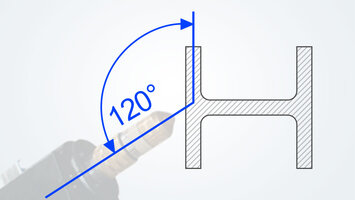

Intuitive and easy to implement: Fully automatic bevel cutting up to 45°

The system allows fully automatic and highly precise bevel cuts up to 45° thanks to MicroStep@s ACTG calibration system. Ma...

Combination solution: Automated sheet, pipe and profile handling

For MicroStep’s laser cutting system MSF Pro different handling solutions for different cut parts are available. The system can...

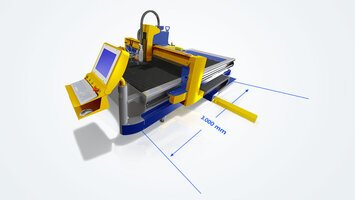

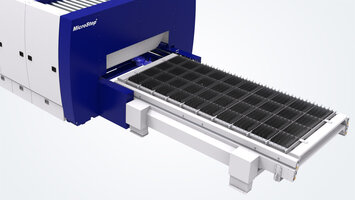

Compact machine with manual loading and unloading

The MSF Compact is available with work areas of 1,000 x 2,000 mm, 1,250 x 2,500 mm and 1,500 x 3,000 mm and is particularly att...

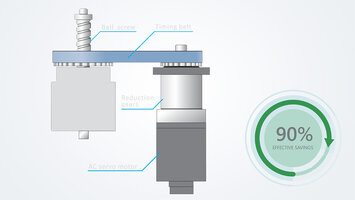

Long-lasting, low-maintenance planetary gears for full dynamics

In order to take full advantage of the dynamics and performance of the AC drive system, the MG series uses long-lasting and low...

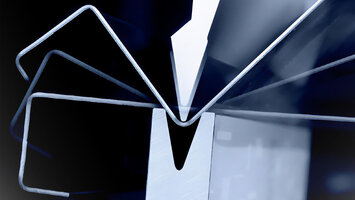

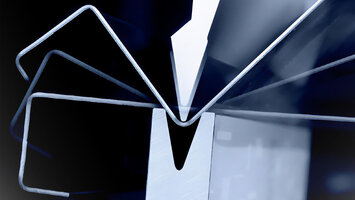

Laser scanner for measuring of the true beam shape

ProfileCut machines are equipped with a 3D laser scanner that measures the exact shape of the beam in the place of cutting. Adv...

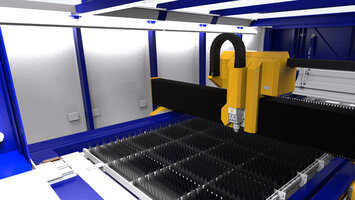

Powerful suction through chuck and the overhead extraction system

MicroStep@s proven suction design for pipe cutting includes direct fume extraction from inside of the pipe through chuck as wel...

Robust, dynamic, and long-lasting machine design

Gantries with extremely high torsion resistance enable high traverse speeds of up to 180,000 mm/minBellows on all axes protect ...

Material handling for particularly large pipes

Combined with a system of the PipeCut series, the MSFeed material handling system is also available in a version for diameters ...

Material handling for pipes and profiles

In combination with the PipeCut, this special version of the MSFeed offers automatic feeding of pipes and closed profiles inclu...

Multi-tool operation with up to 6 oxyfuel torches

Increase your productivity with parallel cutting operationsAutomatic spacing of slave tool stations (option)Individual selectio...

Multi-tool cutting with up to 8 oxyfuel torches

Increase your productivity with parallel cutting operationsPossibility of parallel bevel cutting with several rotator bevel hea...

Mobile safety cabin

In conventional laser cutting machines, the entire machine is enclosed in a fixed housing. By contrast, the MSF Max, to accommo...

Modern plasma systems: Cost-saving operation and maintenance

Cost savings are key @ in comparison with laser systems, modern plasma cutting machines impress with their high cutting speeds ...

MSF Compact: The ideal solution for fast and precise cutting

A powerful, compact laser cutting machine for cutting a wide variety of materialHigh precision and accuracy of parts and contou...

MSLoad: Flexible use for different requirements

The variable and modular design of the entire material handling system makes it possible to adapt the technology to all kinds o...

MSLoop: Universally applicable in plasma and laser applications

MSLoop can be combined with MicroStep cutting systems equipped with plasma or laser cutting technology…

MSSort: Sorting customized to your needs

The MSSort's rotary sorting support has an automatic exchange of gripping tools, each designed to handle different…

MSTower: Customized solutions

The standard MSTower is available in sizes from 3 x 1.5 m to 6 x 2 m and offers space for up to 10 cassettes...

Additional Beveling Process

Parts with thicknesses so big that direct beveling is not possible can still have their edges beveled thanks to MicroStep@s Add...

Pipes and profiles up to 12 t

Depending on the type of pipe cutting device and pipe supports, the CPCut @ PipeCut series can cut round pipes as well as hollo...

Enhanced machine frame delivers even smoother operation

Because a robust machine construction is an important condition for excellent cutting results, in the latest generation of the ...

Smooth and precise positioning for excellent cutting results

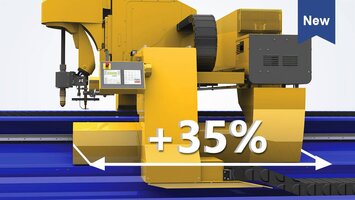

Since a stable machine design is crucial for precise cutting results, the portal guides have been extended by 35% in the longit...

Even more compact in design, even more room to work

Space is costly so we designed the MasterCut Compact as a compact stand-alone solution. Less space needed for control consoles,...

Optimized safety: technology protects the operator

Jede Zone verfügt über einen separaten Zugang in den umzäunten Bereich, der erst entriegelt wird, nachdem alle Maschinen innerh...

Material fixation options for easy use

The material can either be fixed on the table with mechanical clamps or optionally locked on an MDF pad via a vacuum system. Th...

Precise pipe & profile cutting up to Ø 1,000 mm

Enhance your production range by adding pipe and profile cutting optionConvenient cutting program creation with MicroStep@s 2D ...

Precise dome processing up to 6,000 mm diameter

The sturdy machine frame and gantry construction of the MG series enables dome processing up to 6,000 mm diameter. Different ty...

Durable high-precision components

Rustproof chrome plating of linear guidelines helps to protect them against wear caused by abrasive and corrosion. In addition,...

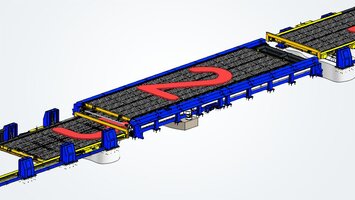

Reduced downtimes: Synchronous loading, processing and unloading

The system consists of three separate work areas that allow simultaneous loading/unloading and pricessing of workpieces, e.g. ...

Pipe and profile cutting

Various pipe and profile cutting options in combination with sheet processing or as a standalone pipe cutting solutionCutting o...

Remote Diagnostics

With CyberFab@ and numerous remote maintenance modules, MicroStep offers the best foundation for fast and competent help via re...

Fast and precise bevel cutting with plasma and oxyfuel

Fully automatic and highly precise weld edge preparation with rotator and 3D rotator bevel tool stations with auto-calibration ...

Fast and precise bevel cutting with plasma and oxyfuel

Fully automatic and highly precise bevel cutting up to 50° (plasma rotator) or up to 60° (oxyfuel rotator)@Bevel cuttin...

Standard AC drives: Increased agility and dynamics

Standard AC drives from Panasonic ensure high drive performance and the best dynamics - even under tough environmental conditio...

Solid and highly resilient: The CNC cutting table of the Compact series

Due to the solid construction, material thicknesses of up to 100 mm can also be easily realized on the MasterCut Compact series.

DS-B: Automated drilling and marking of hollow profiles

The DS-B series, a special version of the DS machine, was designed for automatic dual drilling, tapping and micro-percussion ma...

Economical operation and maintenance thanks to air plasma

Cost saving in all points: Modern air plasma systems deliver cost-effective cuts because no expensive plasma gases are used. De...

Systems for even more efficiency: Automatic nozzle change

In order to increase the degree of automation and thus further enhance productivity, our laser systems can be equipped with an ...

Technologies for even more security

Safety is the top priority in material handling. The system is secured by lockable fences and optical barriers that …

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure consi...

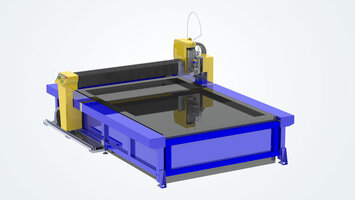

Optional water table designs

Depending on your requirements, different cutting table designs are available for the AquaCut series:Galvanized or stainless st...

Stiffened portal design for an absolutely precise cutting pattern

The MG series has a rigid gantry construction. In comparison to the previous generation of the machine, the stiffness of the ga...

Laser bevel head for bevel cuts up to 45°

V- and X-bevels as well as complex Y- or K-bevels up to 45° with micro jointsAuto-calibration of tool geometry (ACTG@) feat...

Vertical design saves workshop space

The vertical routing machine MicroMill-V is available as a particularly space-saving routing solution. The dynamics of the stan...

In 2D and 3D: versatile configuration options

For precise bevel cuts and efficient weld seam preparation up to 45°, it is possible to provide the WaterCut with a 3D cutt...

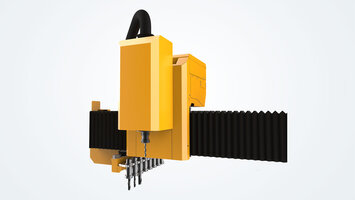

Fully automatic drilling up to Ø 20 mm and tapping up to M16

Fully automatic drilling solution for laser machinesDrilling up to Ø 20 mm, tapping up to M16 and countersinkingTurret head wit...

Fully automatic drilling up to Ø 30 mm and tapping up to M20

Fully automatic drilling solution for the MSF Max machineDrilling up to Ø 30 mm, tapping up to M20 and countersinkingAutomatic ...

Fully automatic drilling up to Ø 40 mm and tapping up to M33

The fully automatic drilling solution provides a substantial added value for your production. Before the parts are cut, precise...

Fully automatic drilling up to Ø 60 mm and tapping up to M30

DRM machines can be delivered in a special version with a drilling table and a selection of powerful drilling heads with powers...

Fast and precise bevel cutting with plasma and oxyfuel

Fully automatic and highly precise weld edge preparation with rotator and 3D rotator bevel tool stations with auto-calibration ...

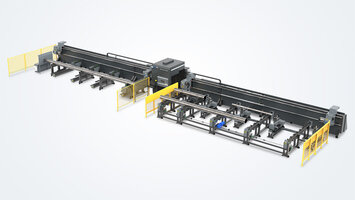

Automatic loading, feeding and unloading

The PipeCut series can be fully automated via handling systems and Machine Production Management (MPM) software, including:Load...

Beam processing automation

The machine can be fully automated via handling systems and Machine Production Management (MPM) software, including:Loading of ...

Cutting with plasma up to 440 A and oxyfuel up to 200 mm

The machine offers excellent cutting results by utilizing both high-definition and conventional plasma sources, with an advance...

Cutting with plasma up to 800 A and oxyfuel up to 300 mm

CombiCut machines are designed to withstand high workloads in multiple-shift operations including multi-torch parallel oxyfuel ...

MSE SmartFL: High-quality 2D laser cutting

The MSE SmartFL is a powerful, reliable and extremely economical fiber laser cutting system from MicroStep Europa.

Highly dynamic machine gantry and solid, durable frame construction

A cast aluminum gantry guarantees higher stiffnesses with a simultaneous weight reduction compared to similar steel gantries.

High efficiency in spite of strong performance

Highly attractive pricing with comparatively manageable investment and operating costs enables a fast return on investment ...

Top-quality brand-name components

The system owes its high reliability and process safety to the fact that it is equipped entirely with top-quality brand-name ...

Automatic shuttle table with sectional suction system

The shuttle table system consists of two movable cutting tables. These tables change position between ...

Remote Diagnostics

With the control system MSE SmartControl and the extensive remote maintenance modules, MicroStep Europa offers the best ...

Excellent cutting quality on different materials

Thanks to best components, the MSE SmartFL achieves excellent cutting quality on most different workpieces.

Green SmartFactory 4.0: Ready for Industry 4.0

The machine@is more than just an optimal entry into high-quality laser cutting: The series is prepared for the use of IndustryF...

Adaptable: in 3 selectable system formats

To adapt the PL Compact to your production demands in the best possible way, we offer you the possibility to choose between fou...

Compact design and low space requirement

Space is precious – which is why the PL Compact was also designed as a complete stand-alone solution. Less space required for t...

Installed and ready for operation within a short time

Thanks to the easySetup® installation concept, the system is assembled and ready for operation in a short time. A special carri...

High cutting quality, less post-processing

Better cutting quality means less post-processing – components can be further processed with significantly less effort, which h...

Ideal solution for fast and precise cutting of pipes and profiles

Powerful, compact laser cutting system for cutting a wide range of materialsHigh precision and contour accuracy of the cut part...

Pipe and rectangular profile processing with a high automation level

Cutting of pipes (up to 500 mm Ø and 12 meter length) and rectangular profiles (up to 350 x 350 mm)Synchronously rotating motor...

Dynamic, solid and durable machine design

Gantry bridge with extremely high torsional stiffness enables high traverse speed up to 180,000 mm/minBellows on all axes prote...

Laser bevel head for bevel cuts up to 45°

Simple V- and X-bevels as well as complex Y- or K-bevels up to 45° with micro jointsClean and efficient weld edge preparati...

Maximum automation and ergonomics

Automatic focus position and focus diameter for the respective materialAutomation of loading and unloadingAutomatic distance ca...

Pipe processing under water solves slag problem

No more slag accumulation during pipe cutting: With an extremely effective and also cost-efficient solution from MicroStep, the...

The MSF Cut: High-quality 2D laser cutting, process-safe & efficient

The MSF Cut is an efficient fiber laser cutting system that combines reliability, precision and economy. The modern 2D cutting ...

High-quality components from renowned brand manufacturers

High-quality brand components combined with MicroStep's proven smart control and software ensure high reliability and lasting p...

Highly dynamic, massive machine gantry

To ensure high rigidity despite low weight, the gantry bridge is based on welded structural profiles. This combination in conju...

Automatic shuttle table with sectional extraction

The fiber laser cutting system is equipped with an automatic, motor-driven shuttle table as standard. The shuttle table system ...

Outstanding cutting quality - whatever the cutting job

The MSF Cut achieves outstanding cutting quality – regardless of the materials and component geometries to be cut. Due to speci...

Efficient processing with a high degree of automation

Several smart tools help to achieve consistently precise and efficient 2D cuts. Not only does the shuttle table system enable a...

Smart today and also tomorrow – Fiber Laser Cutting 4.0 with the Green SmartFactory

The standard equipment of the MSF Cut includes software tools and interfaces that simplify the daily production process and ser...

More automation, more efficiency

Additional automation solutions are available for the MSF Cut laser cutting system for even higher efficiency. MSF Cut can be u...

2D laser with robust, dynamic and long-lasting machine design

Gantries with extremely high torsion resistance enable high traverse speedsCompact, manually extractable cutting table for conv...

Remote Diagnostics

Thanks to powerful remote maintenance solutions, MicroStep Europe provides fast and efficient support via remote access. Most e...

Modern plasma systems: Cost-saving operation and maintenance

Cost savings are key @ in comparison with laser systems, modern plasma cutting machines impress with their high cutting speeds ...

Excellent cutting quality

Better cutting quality means less post-processing, which helps you to save manufacturing costs. A proper technology is availabl...

Extremely resistant and robust - even with difficult environmental variables

Extreme conditions place high demands on the performance of a cutting system. MicroStep@s EasyCut offers the right solution for...

Ergonomic and uncomplicated: The CyberFab® control system

In addition to the externally mounted control console with ergonomic 24@ touchscreen, the system has additional control units d...

Processing of material thicknesses of up to 300 mm

The robust machine design ensures high process reliability even with material thicknesses of up to 300 mm. Smart temperature ma...

Multi-tool operation with up to 6 oxyfuel torches

Increase your productivity with parallel cutting operationsAutomatic spacing of slave tool stations (option)Individual selectio...

Innovative software solutions: Intuitive and easy operation

Our innovative software solutions simplify the conversion of drawings and cutting plans into finished components, allowing you ...

Pipe and profile cutting

Various pipe and profile cutting options in combination with sheet processing or as a standalone pipe cutting solutionCutting o...

Laser bevel head for bevel cuts up to 45°

Simple V- and X-bevels as well as complex Y- or K-bevels up to 45° with micro jointsClean and efficient weld edge preparati...

MicroStep's machine control system CyberFab®: ergonomic and uncomplicated

Controlling the machine is uncomplicated via MicroStep@s machine control system CyberFab. The machine is operated via the MMI c...

Innovative filter technology

Extraction and filter systems are used wherever metals are processed thermally or mechanically and smoke or dust is generated d...

High power: up to 60 kW laser power for maximum productivity

More laser, more beam force, more power: laser sources with an output of up to 60 kW are available for this series.

A highly efficient solution that guarantees maximum productivity

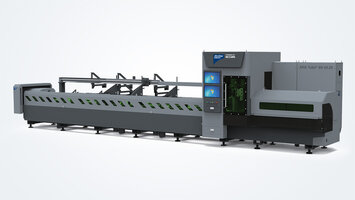

The TubeLINE@is a compact and efficient solution for pipe, profile and beam cutting with numerous advanced technologies for opt...

Pipe, square profile and beam processing with a high degree of automation

Cutting of pipes (up to 580 mm Ø and 12.2 meters long) and square profiles (up to 500 x 500 mm edge length and 12.2 meters tota...

Robust mechanical engineering for excellent process reliability

Technology partner ACCURL has developed robust, pneumatically operated chucks for the TubeLINE series. These can precisely real...

Laser rotator for bevel cuts up to 45°

Depending on the version, the TubeLINE@can be equipped with a laser rotator for bevel cuts from -45° to +45°. In this w...

Maximum automation capability

The optional ATL loading system for the TubeLINE@series works fully automatically and requires no mechanical intervention @ eve...

Special design for particularly large tubes, profiles and beams

The series is available in a special version in which an automated loading and unloading system for particularly large pipes, p...

eB ULTRA: The ideal introduction to high-quality bending

The eB ULTRA series from MicroStep Industry can be equipped with a press force of 250 to 1,250 kN, depending on requirements. A...

State-of-the-art control technology from the quality manufacturer Delem

The standard version of the series is equipped with the latest CNC control technology from the renowned manufacturer Delem: The...

High flexibility: backgauge with up to 6 axes

The backgauge of this series already includes four CNC-controlled axes as standard: X, R, Z1, Z2. This ensures a very high degr...

Sustainable, efficient and fast: all-electric drive

The eB ULTRA is an all-electric system series that is technically equipped to the highest level and impresses with its ease of ...

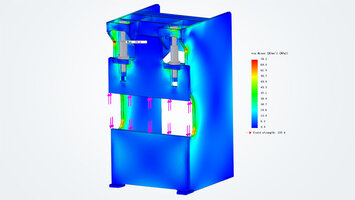

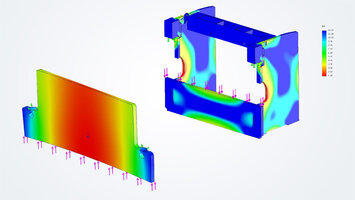

Top-level mechanical engineering thanks to 3D CAD modeling techniques

Thanks to modern 3D CAD design with integrated analysis tools, potential stresses and deformations can be virtually detected an...

Top-level mechanical engineering thanks to 3D CAD modeling techniques

Thanks to the most advanced 3D CAD modeling techniques, including analysis tools, stresses and deformations can be virtually si...

Precision: Constant bending angle over the entire length

The high-precision ePrAX@ control electrohydraulic system works in perfect coordination with the CNC-controlled ACCURL ULTRA@ b...

Precision: Constant bending angle over the entire length

The ultra-precise all-electric drive system of the eB ULTRA series in combination with the Accurl Master@ crowning system compe...

Integrated tool store

Particularly practical: A tool store can be integrated into the side panel of the press brake series, which means that the most...

Integrated tool store

Particularly practical: A tool store is already integrated into the side panel of the new eB ULTRA press brake, which means tha...

Highly dynamic safety equipment

Maximum safety with minimum loss of time: The bending machines are equipped with a visible laser barrier. This IRIS safety devi...

Pressing force: Broad spectrum covered

The EUROMASTER series can be flexibly configured and equipped with a pressing force of between 800 and 4,000 kN, depending on r...

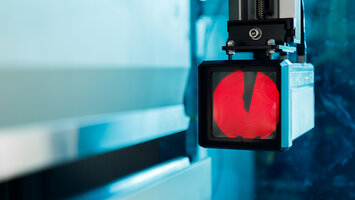

Sustainability & efficiency: electro-hydraulic press drives

The EUROMASTER series is equipped with an innovative electro-hydraulic system that intelligently combines the advantages of two...

MSE CubeFL: The compact solution for 2D laser cutting

The MSE CubeFL is a compact and efficient fiber laser cutting system from MicroStep Europa.

Highly dynamic machine gantry and solid, durable frame construction

The steel frame construction is annealed at over 600 °C to specifically reduce tension. This ensures that the shape remains...

Powerful laser sources with up to 12 kW output for maximum productivity

More laser, more beam force, more power: laser sources with an output of 2 to 12 kW are available for the MSE CubeFL.

Excellent cutting quality with different materials

The MSE CubeFL impresses with high-quality components and delivers precise cutting results on a wide range of components. The s...

Pressing force: Broad spectrum covered

The GENIUS series from MicroStep Industry can be equipped with a pressing force of 600 to 12,500 kN, according to requirements....

State-of-the-art control system from Delem

The GENIUS series comes standard with advanced CNC control technology from Delem. The latest generation of DA Touch controls en...

High flexibility: backgauge with up to 6 axes

In the GENIUS series, the backgauge comprises two CNC-controlled axes as standard: X, R. The backgauge fingers are positioned a...

Sustainability & efficiency: electro-hydraulic press drive

The series is equipped with an innovative electro-hydraulic system that intelligently combines the strengths of both drive tech...

Precision: Constant bending angle over the entire length

The ultra-precise EVO-GO@ electro-hydraulic system in combination with the CNC-controlled Accurl ULTRA@ crowning system compens...

Leistungsstarkes und übersichtliches Werkzeug für alle Parameter

Ein klar strukturierter und intuitiver Dialog ermöglicht die Definition aller Parameter, die die Fasengeometrie betreffen.

Einfache Programmierung von Fasenschnitten

Das Modul Asper Bevel erweitert die Basisversion um ein leistungsstarkes Feature.

Precision: Constant bending angle over the entire length

The high-precision EVO-GO@ electrohydraulic system works in conjunction with the CNC-controlled ACCURL Pro@ bending system and ...

Highly dynamic safety equipment

The SMART press brake has a clearly visible laser safety barrier. The LazerSafe@ safety system reliably prevents jamming betwee...

Pressing force: Wide range covered

The SMART series from MicroStep Industry can be equipped with a press force of 400 to 6,000 kN, depending on requirements. Depe...

State-of-the-art control technology from the quality manufacturer Delem

The standard version of the SMART series features modern CNC control technology from Delem. The latest DA Touch generation impr...

Flexibility: Backgauge with up to 4 axes

In the standard version, the backgauge of this series has two CNC-controlled axes (X and R). The fence fingers are positioned a...

Quality tool clamping systems

MicroStep Industry press brakes are equipped with high-quality clamping systems from ACCURL@ as standard. The upper tool clampi...

SMART Cube X: The compact solution for 2D laser cutting

The SMART Cube X is a compact and efficient fiber laser cutting system from MicroStep Europa.

Powerful laser sources with up to 12 kW output for maximum productivity

More laser, more beam force, more power: laser sources with an output of 2 to 12 kW are available for the SMART Cube X.

Excellent cutting quality with different materials

The SMART Cube X@impresses with high-quality components and delivers precise cutting results on a wide range of components. The...

SmartLINE X: The perfect entry into 2D laser cutting

The SmartLINE X is the perfect entry into high-quality, efficient 2D laser cutting ...

Modular and heavy-duty cutting table

The SmartLINE X shuttle table takes just 15 seconds to extend or retract and can withstand ev

Modular and heavy-duty cutting table

The SMART Giant X sets new standards for large-format laser cutting systems and has a modular design. In the standard version ...

Modular and heavy-duty cutting table

The MasterLINE X shuttle table takes just 20 seconds to extend or retract and can withstand even the heaviest loads ...

High-quality components from renowned brand manufacturers

The system owes its high reliability and process stability to its consistently premium-quality equipment …

High-quality components from renowned brand manufacturers

The system owes its high reliability and process stability to its consistently premium-quality equipment …

High-quality components from renowned brand manufacturers

The system owes its high reliability and process stability to its consistently premium-quality equipment …

European version: Laser sources from Raycus

For the SMART Giant, we rely on Raycus sources that have been specially developed for the European market. With their...

European version: Laser sources from Raycus

For the MasterLINE X, we rely on Raycus sources that have been specially developed for the European market. With their...

European version: Laser sources from Raycus

For the SmartLINE X, we rely on Raycus sources that were developed specifically for the European market: the high-performance C...

European version: Laser sources from Raycus

For the SMART Giant X, we rely on Raycus sources that have been specially developed for the European market. With their...

Ultra-light aluminum portal with intelligent lubrication system

Ultra-high-speed laser cutting systems require extremely fast movements. However, if the rigidity of the cutting gantry is insu...

Safety concept: Protection at top speed!

The MasterLINE X ensures safe and fully compliant operation in accordance with current CE directives...

Safety concept: Protection at top speed!

The SmartLINE X ensures safe and fully compliant operation in accordance with current CE directives ...

ACCURL LasGAM – Efficiency through intelligent gas control

The ACCURL LasGAM system powered by HOERBIGER is revolutionizing laser cutting: Through precise ...

Automatic nozzle change: even greater productivity!

The new auto nozzle changer system from ACCURL revolutionizes nozzle replacement in laser cutting systems. Instead of time-cons...

Excellent cutting quality with different materials

Thanks to its premium components, the SmartLINE X achieves outstanding cutting quality on a wide variety of components. Due to ...

Excellent cutting quality with different materials

Thanks to its premium components, the MasterLINE X achieves outstanding cutting quality on a wide variety of components. Due to...

MasterLINE X – Ultra-high-speed laser cutting

The MasterLINE X is a cutting system with outstanding performance and a process-reliable and extremely robust...

COMING SOON: Laser rotator for bevel cuts up to 45°

The Advanced Bevel Cutting Head from ACCURL, which will soon be available as an option, enables perfect weld seam preparation: ...

COMING SOON: Laser rotator for bevel cuts up to 45°

The Advanced Bevel Cutting Head from ACCURL, which will soon be available as an option, enables perfect weld seam preparation: ...

SMART Giant X – The new dimension in efficiency

The SMART Giant X is more than just a cutting system – it is the key to setting new standards in production...

Steel crossbeam with intelligent lubrication system

The ACCURL steel crossbeam with intelligent, automated lubrication system sets new standards for large-format laser cutting sys...

Safety concept: Protection at top speed!

With ultra-fast acceleration and parallel processes such as loading and unloading, a conventional ...

Powerful laser sources with up to 12 kW output for maximum productivity

More laser, more beam force, more power: laser sources with an output of 2 to 12 kW are available for the SMART Cube X.

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization