Laser cutting of tubes, profiles and beams

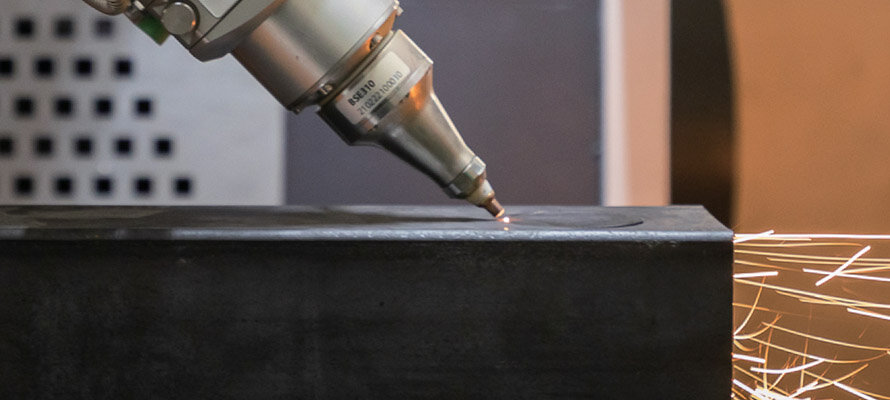

Tubes, profiles and beams are available in various dimensions, materials and designs and are used in a wide range of industries, such as the automotive and construction sectors. Cutting a wide variety of material geometries using fibre lasers is a modern and extremely efficient processing method.

Tube, profile and beam processing

Pipes, profiles and beams are different types of semi-finished products that are used in different areas. Profiles and beams have an elongated structure with a specific cross-sectional shape. They are often made of metal and are available in various shapes such as U, L, T or I shapes. They are used in the construction industry in particular to create load-bearing structures for buildings, bridges, towers and other structures, as they offer strength and stability at a relatively low weight. Tubes have a hollow cylindrical structure and are usually made of inflexible materials such as metal, plastic or glass. They are used in particular as supply lines for the transport of liquids or gases or in the construction industry for scaffolding, balconies, banisters and more.

In the conventional production of tubes, profiles and beams, several downstream work steps such as sawing, punching and drilling the components used to be necessary. These individual steps can be replaced by the modern laser cutting be summarised in one work process and saves processing time and production costs. Laser cutting of tubes, profiles and beams is also a very precise processing method and offers a high degree of accuracy and repeatability. Time-consuming reworking, which is sometimes necessary with conventional production methods, can usually be omitted. Tubes, beams and profiles often have to be welded to other pieces. Thanks to the laser cutting process, weld seams can also be reliably prepared in openings or recesses.

Advantages: Laser cutting of tubes, profiles and beams

- Precise cuts with minimal tolerances

- Processing of a wide range of different materials

- Cutting of complex shapes and contours

- High production speed and efficiency

- Minimal deformation of the materials

- High automation potential

Areas of application for the laser cutting of tubes, profiles and beams

The laser cutting of tubes, profiles and beams is used in a wide range of industries:

- Automotive industry: production of frames, exhaust systems and safety structures

- Aerospace: Complex tubes and profiles for structural components, engines and other parts of aircraft

- Construction industry: Manufacture of steel structures, railings, stairs, beams and other architectural components

- Furniture industry: construction of steel furniture such as tables, chairs, shelves and bed frames

- Power generation: Components for wind turbines, solar plants, power plants and other energy generation facilities

- Medical technology: production of medical devices, surgical instruments and implants

- Food industry: Tubes and profiles for processing plants, conveyor belts and other equipment

- Electronics industry: production of housings, heat sinks and brackets

These applications are just a few examples, and the use of laser cutting technologies for the production of tubes, profiles and beams in various industries is steadily increasing due to their precision, speed and versatility.

Tube, profile and beam processing using fibre laser technology

The MSE TubeFL series

Reliable and fast 2D and 3D machining of tubes, profiles and beams. The MSE TubeFL is a compact and efficient solution for the production of high-precision parts and, depending on the version, has an extremely high degree of automation.

- Tube & profile processing

- Carrier processing

- 2D cutting

- 3D cutting

- Marking, labelling

- Material handling

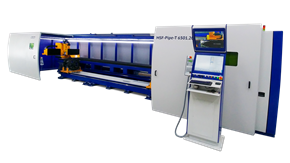

The MSF Pipe series

Pipe and profile processing at high cutting speeds. The MSF Pipe can be used to realise the finest contours and openings as well as precise bevel cuts. An optional extension for processing sheet metal is also available.

- Sheet metal processing

- Tube & profile processing

- 2D cutting

- 3D cutting

- Marking, labelling

- Scanning, reading

- automation

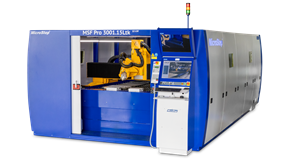

Die MSF Pro Baureihe

Mit der MSF Pro Baureihe können sowohl Bleche, wie auch Rohre und Profile geschnitten werden. Der präzise Laser-Allrounder punktet sowohl mit Multifunktionalität wie auch mit hoher Schneidgeschwindigkeit.

- Blechbearbeitung

- Rohr- & Profilbearbeitung

- 2D-Schneiden

- 3D-Schneiden

- Bohren, Gewinden, Senken

- Markieren, Beschriften

- Scannen, Lesen

- Materialhandling

- Automatisierung

You might also be interested in:

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

MSE TubeFL

MSE TubeFL

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization