Smart 2D laser for maximum precision

Investment in a further laser cutting system from MicroStep Europa

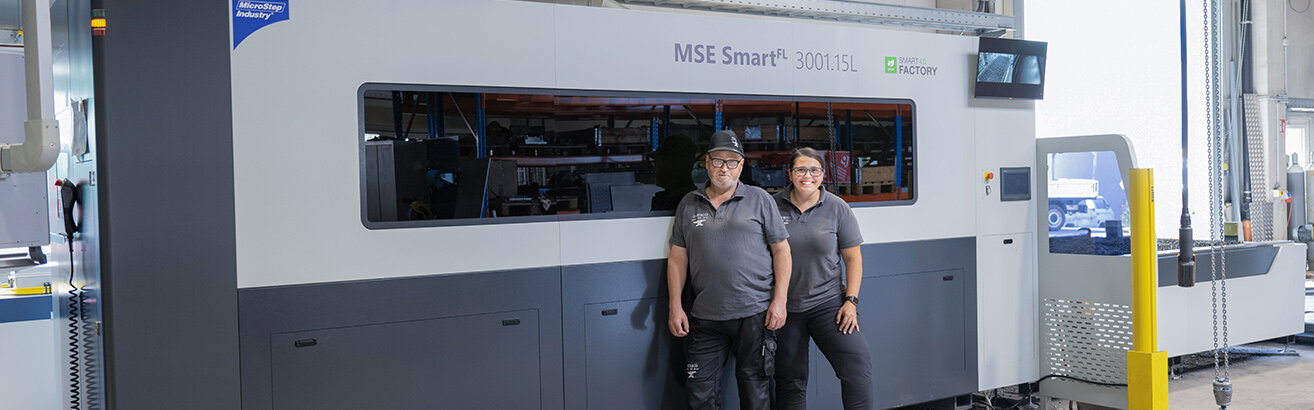

The combination of MSF Compact and MSE SmartFL enables Schmid OG, a carpentry firm in the Stubai Valley, to optimally meet a wide range of customer requirements.

Published 27.11.2024 | Ramona Langhammer

Company profile:

Austria

The Schmid OG is located in Fulpmes in the Austrian Stubai Valley. Here, the company manufactures workpieces for the agricultural and automotive industries, among others, and also offers powder coating and forging in addition to plasma and laser cutting.

Two MicroStep Europa laser systems are in use at Schmid OG in the Stubai Valley. The company uses the MSF Compact for small parts with a material thickness of up to 5 mm, while the MSE SmartFL is used to cut larger components with higher material thickness, particularly for contract manufacturing.

Machine profile:

MSE SmartFL series

- Working area 3,000 x 1,500 mm

- 2D laser cutting

- Raycus fiber laser – 8 kW

- Automatic shuttle table

Schmid OG is based in Fulpmes in Tyrol: the family business is well positioned to offer its customers a range of metal processing services. These include cutting, pressing, punching, folding, painting and even forging. For more than 10 years, the company has also had its own cutting department. MicroStep's plasma technology was the starting point, and in 2022 a compact laser cutting system completed the machine park for the time being. Due to the good order situation and increased customer requirements, particularly in the automotive industry, the family-owned company has now decided to purchase a smart 2D laser from MicroStep Europa.

Forging, bending, pressing, punching and more – more than 20 years ago, Gerhard Schmid took over a blacksmith's shop founded in 1910 in the Stubai Valley, about 20 km south of Innsbruck. Production has been continuously modernized and expanded to manufacture high-quality precision parts and series for customers in the mountaineering, automotive and tool industries. Particular emphasis is placed on the individual adjustment of all production parameters to achieve a result that precisely meets the customer's requirements.

Investment in plasma and laser technology

In 2012, Schmid OG also decided to bring cutting in-house. After intensive research, the company came across MicroStep and decided to purchase a 2D plasma cutting system from the MasterCut series. In order to meet the increasing demands, particularly from the automotive industry, for higher accuracy, the metal fabricator decided to invest in a laser cutting system almost ten years later. It quickly became clear to the two managing directors, Gerhard Schmid and his daughter Marie-Theres Schöpf, that it should be another MicroStep machine, and so the company put an MSF Compact series system into operation in February 2022.

„You can't make an omelette without breaking eggs“

However, the demand for cutting thin sheets with ever more precise requirements, both for in-house cutting and for contract manufacturing, was constantly increasing. And so, just one year later, a further investment was needed to meet the volume of orders. Based on the good experiences with the cutting systems already purchased, it quickly became clear to Schmid OG after a brief comparison with other manufacturers: it would be another laser system from MicroStep Europa. “You can't make an omelet without breaking eggs – a problem can always arise and at MicroStep Europa we know that we can rely on getting help right away,” says Marie-Theres Schöpf, managing director of Schmid OG. ”With other manufacturers, we didn't know where the support was and if or when someone could help us if something came up.” After consulting with area sales manager Alois Bergmann, the family business decided on an MSE SmartFL 2D laser cutting system with an 8 kW laser.

Two laser cutting systems for different requirements

The new laser cutting system has been in use since mid-June 2020 at the same spot where the plasma cutting system reliably performed its services for many years – just a few steps from the existing MSF Compact. The company cuts small parts with a material thickness of up to 5 mm on the compact 2D laser – larger components with a higher material thickness, especially for contract manufacturing, on the MSE SmartFL. Just one month after commissioning, the machine was already running at around 70 percent capacity. “We receive a lot of orders from the agricultural industry, especially in spring and fall, so we expect a further increase in capacity here,” says Schöpf. Regarding the purchase of the new laser cutting system, she concludes: “Everything went really well again. Even the fact that the delivery date could be brought forward – it's just always very good communication.”

“You can't make an omelet without breaking eggs – a problem can always arise and at MicroStep Europa we know that we can rely on getting help right away.”

Marie-Theres Schöpf

Managing Director | Schmid OG

THE HIGHLIGHTS OF THE MSE SMARTFL AT A GLANCE:

8 kW cutting power for heavy-duty 2D laser cutting with automatic shuttle table

For precise and fast 2D cutting of sheet metal, Schmid OG relies on the MSE SmartFL laser series from MicroStep Europa. The fiber laser system for high-quality 2D laser cutting is characterized by an automatic shuttle table for loading and unloading sheets, a modern MSE SmartControl machine control system, high-quality components from well-known manufacturers and the latest Intel processor technology. The Schmid OG chose a working area of 3,000 x 1,500 mm and a powerful Donaldson DFPRE 9-R-SP filter system with 7.5 kW nominal power. An RFL-C8000M-HP from Raycus with 8 kW cutting power serves as the laser source.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization