News

Week after week, new MicroStep systems are going into operation around the globe – from small CNC systems for schools and workshops to tailor-made production lines for steel centers, shipyards or the automotive and aerospace industries. More than 100 employees in the research and development department alone ensure that MicroStep is constantly introducing new innovations in the field of cutting technology to the market. In our "News" section, we will keep you up to date on the most exciting developments.

Schweissen & Schneiden 2023: Positive conclusion after a strong comeback

MicroStep reports the world's leading trade fair in Essen as a complete success: The diverse technology presentation around cutting, automation and digitalization was very well received by the trade visitors

Unique technology variety with a digital focus

At the leading trade fair, MicroStep will be showing all four cutting technologies relevant to metalworking (plasma, laser, waterjet, oxyfuel) in 2D and 3D - various topic areas and some digital novelties complete the trade fair offer.

"The package simply fit" for the versatile 3D plasma cutting system

Thanks to the investment in a multifunctional CNC cutting center from MicroStep, Kammerer Tankbau GmbH, based in South Tyrol, can act faster and more efficiently in its tank production.

At record level: MicroStep increases revenue by more than 40 percent

MicroStep Europa GmbH posts significant revenue growth for 2022, invests in staff and infrastructure, and presents new technologies for laser cutting and bending

New date for the OpenDay: MicroStep celebrates in 2024

The grand opening of the new MicroStep CompetenceCenter South has been postponed. The open day of the new technology and logistics center in Bad Wörishofen will now take place on June 13, 2024

MicroStep technology in use for safe nuclear power plant decommissioning

Together with partners, MicroStep develops and produces two automated radiation measuring chambers for the German company EWN to dismantle the nuclear power plant in Greifswald/Lubmin

"We would always choose this series again, the overall package simply fits".

Humberg GmbH is the market leader in the field of tree protection systems for urban areas. For fast cutting, the company relies on the powerful entry-level laser MSE SmartFL

Sought and found: Two state-of-the-art 3D laser cutting systems

For the rapid production of high-precision series parts, steel specialist Ferro Service Sp z o.o invested in two fiber laser systems for flexible weld edge preparation on different sheet thicknesses

EuroBLECH 2022: Unique technology offering presented

The strategy of presenting the relevant cutting technologies (plasma, laser, waterjet, oxyfuel) in 2D and 3D at the leading exhibition and combining them with other innovations was a complete success. MicroStep books EuroBLECH as a complete success

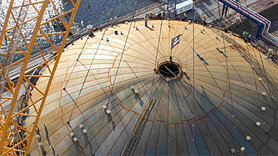

Tank and pressure vessel specialist invests in modern and flexible cutting solution

Engicon nv (Geldof) built a new custom-fit hall especially for the new cutting system – the 3D plasma cutting system from MicroStep with Tecloga shuttle table saves a lot of time and optimizes production thanks to the plasma rotator and other technologies

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization