Great exhibition restart after the pause

EuroBLECH 2022: Unique technology offering presented

The strategy of presenting the relevant cutting technologies (plasma, laser, waterjet, oxyfuel) in 2D and 3D at the leading exhibition and combining them with other innovations was a complete success. MicroStep books EuroBLECH as a complete success

Published 07.11.2022 | Erich Wörishofer

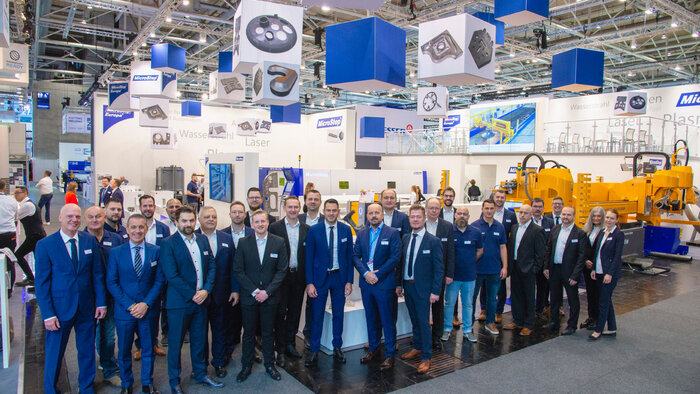

MicroStep successfully presented itself with an immense variety of technologies at the EuroBLECH 2022. After a three-year exhibition absence, the "Partner for Cutting and Automation" showed a unique range of technologies at the largest fair appearance in the company's history. This was very well received by visitors: 2D and 3D cutting systems in plasma, laser, waterjet and oxyfuel were just as much in demand as the latest digitalization solutions or the bending press technology from MicroStep Industry, which was presented for the first time. "A successful appearance at the exhibition after the break – our strategy of showing visitors exactly which solutions fit their profile with our broad product portfolio has fully proven itself," stated Johannes Ried, Managing Director of MicroStep Europa GmbH.

Unique was the buzzword heard most often throughout MicroStep's exhibition presence. 2D cutting, bevel processing with oxyfuel, plasma, laser and waterjet, systems for scanning and marking, for sheet metal, pipe, profile and dome processing. The highly interested visitors were able to gain a first-hand impression of all the topics. Whether small entry-level systems or complex multifunctional wonders; whether the industry pioneer in terms of flexibility and process reliability, the MG plasma oxyfuel cutting system, or the new bending press systems from MicroStep Industry. "Even if the visitor volume was lower compared to the EuroBLECH 2018, the demand was in the result of higher quality. From managing directors to workshop managers, everyone was enthusiastic about the range of solutions we presented. Within just a few meters, they experienced how modern systems can improve their production," said Johannes Ried. "A successful appearance at the exhibition after the break – our strategy of showing visitors exactly which solutions fit their profile with our broad product portfolio has fully proven itself," stated Johannes Ried, Managing Director of MicroStep Europa GmbH. This unique constellation can also be experienced in a 1:1 consultation in the two training and demonstration centers in Bavaria and North Rhine-Westphalia, Germany.

At the machine shows at EuroBLECH, MicroStep showed state-of-the-art plasma, laser, oxyfuel and waterjet cutting systems live in action – in 2D and 3D. Four exciting exhibition days lie behind the MicroStep team.

Five systems in live operation and

other eye-catchers

MicroStep had a total of five cutting systems in their luggage: The multifunctional MG including plasma rotator and oxyfuel rotator for 3D processing of sheet metal, pipes, profiles and domes, the 3D laser cutting system MSF Pro, the new 3D waterjet cutting system WaterCut as well as the space-saving 2D laser solution MSF Compact and its plasma counterpart the MasterCut Compact. Within a few steps, unique experience islands were created around the two-story stand, where German-speaking and also international visitors were given intensive and technology-independent consulting. An eye-catcher was the cutting sample of a dished end with a diameter of 2,000 mm and different bevel geometries, holes and free contours, which was cut on the DRM series, as well as a milled and drilled part cut with the DRM Max.

"A successful appearance at the exhibition after the break – our strategy of showing visitors exactly which solutions fit their profile with our broad product portfolio has fully proven itself. From managing directors to workshop managers, everyone was enthusiastic about the range of solutions we presented. Within just a few meters, they experienced how modern systems can improve their production."

Johannes Ried

Managing Director | MicroStep Europa GmbH

"The great interest shown across all our presented technologies confirms our fundamental strategy in research and development: The amalgamation of state-of-the-art digital solutions with increasingly versatile systems across all cutting processes for energy-saving and efficient production, where users do not have to make any compromises in terms of quality and process reliability," said Igor Mikulina, Managing Director of MicroStep Europa and President of the Board of Trustees of the IndustryFusion Foundation. The latter presented itself for the first time at EuroBLECH with a joint stand with a total of seven members as well as IT partners Intel and SUSE. The first manufacturer-independent open source networking solution IndustryFusion, which makes smart products, smart factories and smart services a reality, was presented.

The presented cutting systems

The multifunctional all-rounder MG | 3D processing on sheet metal, pipes & profiles with plasma rotator, oxyfuel rotator as well as with laser scanner, laser marker, needle marker, boring mill and the new MicroStep vibration table

The laser allrounder MSF Pro | 3D processing with laser rotator on flat material

The multi-talent AquaCut | 3D processing on flat material with 5-axis waterjet rotator

The entry-level precision system with minimal space requirements: MSF Compact | 2D processing on flat matieral

The space-saving MasterCut Compact | 3D processing with plasma rotator on sheet metal

Premiere: The innovations presented at EuroBLECH 2022

CyberFab Manager: The digital heart of MicroStep production systems is entirely new: the suite of digital tools and apps enables efficient operation as well as planning and management of MicroStep-based systems through automation and digitalization.

Waterjet cutting system WaterCut: The name WaterCut was already part of the waterjet portfolio, but the series has been redesigned, is available in new formats and can now also be equipped with a precise 3D cutting head for bevel cuts.

Bending presses: MicroStep Industry presented for the first time to the public its new bending press series – namely the universal high-end bending press GHL. Innovative assistance systems enable top quality and reliability and reduce the demands placed on operators.

Review of the EuroBLECH 2022 in the video

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization