Market leader for tree protection systems

"We would always choose this series again, the overall package simply fits".

Market leader for tree protection systems

Published 03.02.2023 | Erich Wörishofer

Company profile:

The roots of Humberg GmbH, based in Nottuln, Münsterland, go back to 1882. Founded as a forge and machine factory, the focus was placed on foundry work in the middle of the 20th century. For more than 25 years, the specialist company has also been active in the field of urban tree protection and the design of squares, and is a market leader with innovative systems for sustainable tree protection paired with preventive measures for long-lasting tree growth.

Whether on squares, avenues, shopping centers or schools in large cities and small communities, Humberg's tree protection systems make a visual statement and, above all, ensure the right underground and environmental conditions so that trees can thrive for a long time in urban areas.

Machine profile:

MSE SmartFL Baureihe

- Working area 3,000 x 1,500 mm

- 2D fiber laser – 4 kW

- Automatic shuttle table

When architects, urban planners, companies or municipalities want to make streets and squares more livable with trees, then products from Humberg GmbH come into play all over Germany. This is because the family-owned company from North Rhine-Westphalia is the market leader in the field of urban systems for tree protection and square design. Individual systems are necessary to meet the needs of different tree species and to adapt the protection to the environmental variables for long-lasting life. For this reason, flexibility and speed are also elementary in the right cutting technology. After existing good experiences with MicroStep, the specialist company has opted for the new MSE SmartFL laser series. "I am very satisfied with the solution," says Franz Humberg.

At hundreds of locations in Germany and neighboring countries, the innovative products of Humberg GmbH provide long-lasting greenery in the midst of urban areas. No matter whether it's Mercedes Square or Humboldt University in Berlin, Hafen-City in Hamburg or numerous other squares, avenues, shopping centers or schools in large cities and small communities. Because the family-owned company based in North Rhine-Westphalia is an expert in tree protection and square design and offers complex solutions for all aspects of urban tree planting.

With the tree knowledge to green results for decades

When it comes to planning and design, Humberg GmbH benefits from three decades of intensive collaboration with luminaries in the field of root systems and tree growth "Our strength is our know-how about trees. We know what a tree needs to be able to grow for 30 years at this location with the respective subsoil and environmental conditions," explains managing director Franz Humberg. The family-owned company develops and sells its own systems and is now the market leader in the field of urban products for tree protection. The task of creating solutions that meet the individual situation is a constant challenge. "Everywhere, correctly, more and more trees are being planted. Everywhere where a tree actually cannot grow because we want to use the space as a traffic area," Franz Humberg describes the situation. Roots receive enclosures and water storage systems, trees are protected from several sides. There are many questions to be answered: Which tree species with which root system will be placed? What is the subsoil like? How is the irrigation and drainage? What forces are affecting the area from above? Is it a busy park area with tons of traffic or a quiet pedestrian zone?

Individual production necessary, therefore speed and flexibility elementary

These and more questions are answered by the specialist staff in terms of the longevity of the trees. Although Humberg GmbH relies on proven basic concepts, these must be individually adapted to the respective situation. "For this reason, pre-production and warehousing do not make sense for us. We rely on cutting quickly in-house," says Franz Humberg.

From purchasing to plasma technology and to the desired laser solution

In the early years, the cutting parts were still purchased. After a larger location became necessary due to the good development of the company, the management decided to invest in an own cutting system. More flexibility, more speed was the order of the day. At first, a used laser cutting system was considered, but after intensive consultation, the decision was made in favor of a 2D plasma cutting system of the MasterCut series from MicroStep. The products were adapted to the strengths of this technology. The installed Kjellberg HiFocus 161i neo plasma power source was upgraded to the SilentCut noise-reduced system. "Our employees really liked that. That was good," says Franz Humberg.

As of April 2017, the plasma cutting system was running, but the demand for laser parts grew steadily despite the in-house cutting system and production adjustments. "Every year we increased in sales and realized we were purchasing more and more after all. We couldn't handle a third of the cutting orders." So the idea of investing in our own laser cutting system grew again. But the constellation of performance, size, price and manufacturer we were looking for was not to be found.

It was not until MicroStep Europa presented its new MSE SmartFL laser series, the powerful entry-level laser, to the market in 2020 that all the desired parameters came together. "Everything fits here. A 2D laser with shuttle table at good conditions. Plus the physical proximity to MicroStep, which I have always liked, everything has always been good. I am very satisfied with the solution," says Franz Humberg. MicroStep Europa took care of selling the still young plasma cutting system and installed the new fiber laser system in August 2021.

On the new MSE SmartFL: "Everything fits here. A 2D laser with shuttle table at good conditions. Plus the physical proximity to MicroStep, which I have always liked, everything has always been good. I am very satisfied with the solution.“

Franz Humberg,

Managing Director | Humberg GmbH

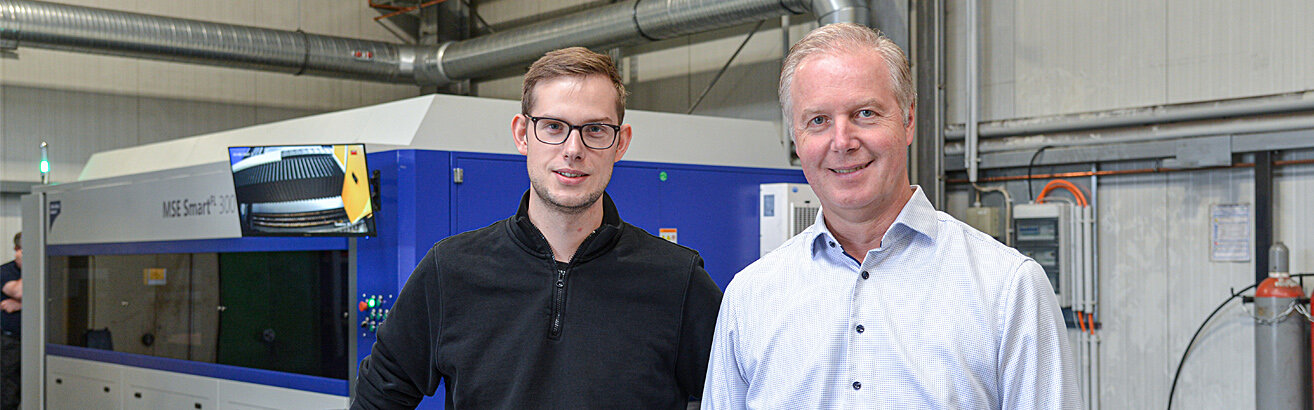

Strong start with 200 tons of cutting results in the first five months

Since then, Michael Humberg – the next generation of Humbergs in the company and, as the machine park manager, also responsible for the laser cutting system – has been working intensively on production every day. "The machine hasn't been down for a day yet. By Christmas, we had already cut 200 tons," he says. The company currently cuts only steel in the 5 to 10 millimeter range. Mostly 2 x 2 meter plates are produced. Primarily single-shift, with additional hours as needed. "It all goes through cleanly and pleasantly. It's really wonderful. Even if you have questions, the service technicians always help." The laser source installed is a system from IPG, the YLR 4000, with 4 kW cutting power.

Michael Humberg's conclusion: "We would always choose the series again because the overall package simply fits."

OVERVIEW OF THE HIGHLIGHTS OF THE MSE SMARTFL LASER CUTTING SYSTEM:

Powerful entry into high-quality laser cutting with the

For precise and fast 2D cutting of steels in sheet thicknesses from 5 to 10 millimeters, Humberg GmbH relies on the latest laser series from MicroStep Europa GmbH: the MSE SmartFL. The fiber laser cutting system is a powerful entry into high-quality 2D laser cutting with an automatic shuttle table and exclusively high-quality components from renowned manufacturers for long-lasting and reliably precise results. Humberg opted for a version with a working area of 3,000 x 1,500 mm. A YLR 4000 from the German manufacturer IPG Photonics with 4 kW cutting power is integrated as the laser source. The MSE SmartControl machine control system – a modern, intuitive user interface – guarantees that cutting plans can be reliably and highly effectively converted into finished components.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization