MicroStep CompetenceCenter® South

Experience our technological solutions live!

A new era began at the MicroStep CompetenceCenter South in 2023. The existing training and demonstration center was replaced with the commissioning of the new technology and logistics center. Welcome to the new MicroStep CompetenceCenter South in Bad Wörishofen – a stone's throw from the company headquarters.

MicroStep Europa has invested more than 6 million euros in the 3,700 m² technology and logistics center, including an Industry 4.0 demo factory. Attractive office space has been created on 800 m², the logistics center has 1,500 m² of storage space and has been equipped with state-of-the-art systems. Innovative CNC cutting systems and automation solutions are available for training and demonstration purposes in the 1,350 m² showroom – the Industry 4.0 demo factory also allows visitors to experience examples and benefits of a networked production environment.

Schedule your visit!

Would you like to experience live how a multifunctional cutting system from MicroStep can help you to improve your productivity of processing sheet metal, pipes, profiles and domes? Would you like to see with your own eyes the possibilities offered by modern cutting systems (plasma, laser, oxyfuel, waterjet) in 2D and 3D and which solution is the right one for your requirements? Would you like to find out more about the innovative deburring systems, the new bending technologies from MicroStep Industry and revolutionary digitalization solutions for your production?

Then make an appointment to visit us right away! Our experts look forward to welcoming you at the MicroStep CompetenceCenter South!

We also welcome you to our CompetenceCenter North at our branch in Dorsten (North Rhine-Westphalia) for training courses and demonstrations!

Johannes Ried

Johannes RiedManaging Director

MicroStep Europa GmbH

„We are keen to equip customers for the demands of tomorrow with our innovative systems and help them to become even more productive and efficient. In the new CompetenceCenter South, we have the opportunity to present our versatile products in one place. With a unique range of technologies, we offer an ideal contact point for large and small metal processing companies from southern Germany, Austria and Switzerland.“

The exhibits in the showroom: cutting and automation systems as well as bending and deburring technologies live in action

The following systems are currently on display at the Bad Wörishofen site:

Plasma & oxyfuel cutting I MG - the multifunctional all-rounder

The multifunctional all-rounder from the MG series can be experienced live in the showroom. MicroStep's top product is equipped with a plasma rotator and an oxyfuel rotator for 3D processing of sheet metal, pipes, profiles and container bases. Other technologies for drilling, countersinking, threading and laser marking are also integrated.

More about the MG series

Laserschneiden I MSF Pro – innovativ & vielseitig multifunktional

Precision, versatility and automation: this is what the MSF Pro fibre laser cutting system stands for. With an enormous vertical range of manufacture, it can be configured for the 3D processing of sheet metal, tubes and profiles – including automatic material handling. A laser system including a laser rotator for bevel cutting up to 45° and other additional functions for precise and reliable results as well as efficient production can be experienced live in the showroom.

More about the MSF Pro series

Waterjet cutting I WaterCut - The waterjet performer

The new waterjet cutting system from the WaterCut series is also ready to unleash the power of water using a new 3D cutting head and demonstrate its precision on different materials and thicknesses.

More about the WaterCut series

Laser cutting 4.0 I MSE SmartFL – 2D laser cutting at the highest level

Powerful, reliable and economical fibre laser cutting 4.0: this is made possible by the 2D cutting system with high-power potential up to 60 kW laser output. The series is optimised for the use of IndustryFusion and is therefore already ideally equipped for the production of the future. A version with a 12 kW laser source is being used live in the showroom.

More about the MSE SmartFL series

Laser cutting I MSE CubeFL – 2D laser cutting in a compact space

Maximum precision and efficiency with minimum space requirements. The MSE Cube fiber laser cutting systemFL is also fully digitally networked. A version with a processing area of 1,500 x 3,000 mm and a 6 kW laser source can be experienced live at the CompetenceCenter.

More about the MSE CubeFL

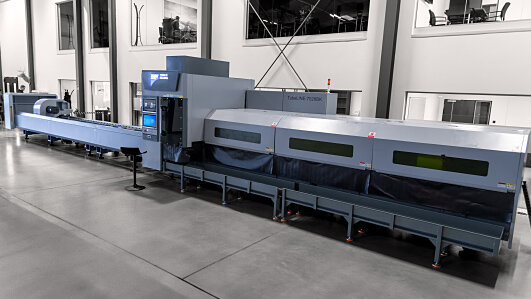

Tube lasering I MSE TubeFL – Tubes, profiles and beams

High-precision and fast 2D and 3D machining of tubes, profiles and beams - this is what the MSE TubeFL developed. On display in the showroom is a configuration with 6 kW laser power, which enables the precise processing of tubes up to 7.5 meters in length and 245 mm in diameter as well as profile cutting up to 7.5 meters in length and an edge length of up to 175 mm.

More about the MSE TubeFL

Surface processing I Lissmac SMD 3 – the universal sanding and deburring machine

Lissmac systems score with flexibility and efficiency and can be used for deburring, strong edge rounding, slag removal, oxide layer removal and surface finishing. The SMD 3 was specially designed for thick sheet metal processing, delivers impressive results and can be easily integrated into automation solutions.

More about the SMD 3

CompetenceCenter Bad Wörishofen

MicroStep guest service

Discover Bad Wörishofen and surroundings with our guest guide!

We gladly assist you in booking a hotel room!

Contact our administration & events department at:

+49 8247 96294-01

Hotel recommendations

Hotel-Gasthof Adler

Parkhotel Residence

Steigenberger Hotel „Der Sonnenhof“

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization