Asper Basic® 2D CAM software

Asper Basic | 2D CAM software for intuitive and efficient manufacturing

MicroStep‘s 2D CAM software Asper is the ideal tool for easy and fast creation of CNC programs for various cutting and supplementary technologies. Even in its basic version, Asper offers powerful functionalities for 2D cutting that can be further extended by a variety of specialized modules (e.g. bevel cutting module, pipe cutting module, multi-torch cutting module and more) and even customized to fit a customer’s special requirements.

The intuitive structure and sophisticated features make Asper a modern and powerful tool for CNC programming.

Use the full potential of your MicroStep cutting system:

In addition to the countless possibilities and tools which Asper offers in its basic version, the software can be expanded with additional modules.

• Pipe & profile processing (2D and 3D)

• Dome processing

• Weld seam preparation

• Multi-torch operation

• Macro library for HVAC and pressure vessel construction

All add-ons can be quickly and comfortably activated directly on your machine.

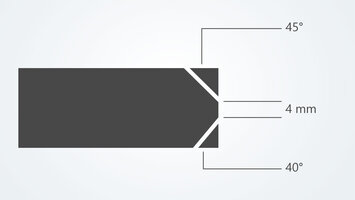

Easy programming of bevel cuts

With just a few simple steps, you can add weld seam preparations to your cutting plans. Just choose the bevel type, angle, and land height.

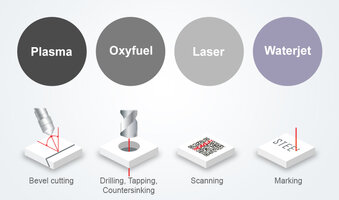

Multi-technology work processes: More efficiency through combined processes

Asper® is designed to take full advantage of all technologies on your MicroStep machine. For example, multiple technologies can be used together in one process.

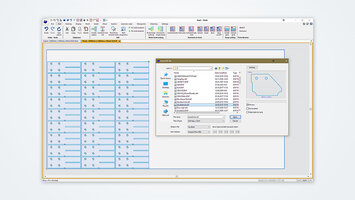

Import of all common CAD formats via network or USB connection

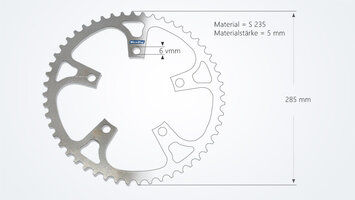

With Asper, you can load your parts in various formats (DXF, ESSI, CNC, DC2, IGES...) from the network or USB storage and quickly convert them into a CNC program.

Numerous macro libraries for faster production

Choose from a large number of standardized components and adapt them to your requirements with just a few clicks, saving time on recurring parts.

Economical plate and residue management

If desired, the components can be nested in a way that allows some of their contours to be cut at once, minimizing the number of lead-ins and lead-outs. This has a positive influence on consumable life and saves cutting time.

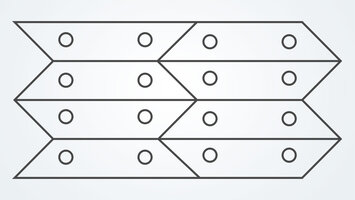

Low waste semi-automatic nesting

The semi-automatic nesting function of Asper places parts on a plate as economically as possible. Cutting plans can be added to or changed with just a few clicks, always with optimized space utilization.

HeatControl® for lower thermal impact

To avoid local overheating of the plate during cutting, the HeatControl® functionality ensures dynamic distribution of the cutting path over the entire plate. This minimizes local heat deformation and protects consumables.

SpeedControl® for higher precision of corners, arcs, and holes

The SpeedControl® functionality regulates the cutting speed on all MicroStep machines to optimize the cutting quality in tight corners and arcs.

Common-cut contours

If desired, the components can be nested in a way that allows some of their contours to be cut at once, minimizing the numberof lead-ins and lead-outs. This has a positive influence on consumable life and saves cutting time.

Quick & easy creation of CNC programs

The Asper Basic 2D CAM software helps you to intuitively convert drawings and cutting plans into finished components so that you can concentrate fully on your products.

Software update contract CAD/CAM

The MicroStep Europa® Software Update Contract CAD/CAM includes regular updates, ongoing improvements and special conditions for the MicroStep software products offered.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization