MicroSteps MG: Energy and building technology specialist "convinced by accuracy and positioning speed"

"Most important link in the production process"

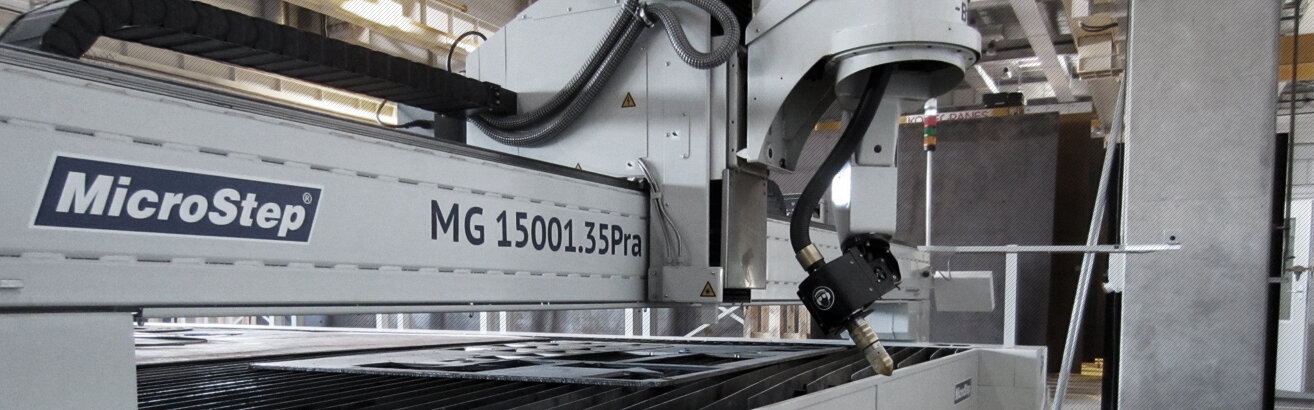

3D plasma cutting system including moving hand plasma cutter: Robert BOSCH GmbH works with MicroStep technology for weld seam preparation up to 50°

Published 17.04.2017 | Erich Wörishofer

Company profile:

Robert-Bosch-Platz 170839 Gerlingen-SchillerhöheGermany

The company was founded in Stuttgart in 1886. The Bosch Group is a technology and service company with approximately 375,000 employees worldwide. Its activities are divided into the four business sectors Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology.

In operation at BOSCH: the MG plasma cutting system with the MicroStep R5 rotator for bevel cutting for weld edge preparation up to 50°.

Bosch Heating Systems LLC has put into operation a new production line for the manufacture of industrial boilers in Russia. For cutting technology, the company relies on a plasma cutting system from MicroStep. "The cutting system is at the very beginning of the manufacturing process and is therefore the most important link," says Stefan Karguth, Project Manager Machine Procurement at Robert BOSCH GmbH.

In an existing BOSCH plant in the Russian city of Engels – about 800 kilometers southeast of Moscow – the BOSCH Thermotechnology Division has invested in a new production line for the manufacture of industrial steam boilers. "The location is ideal, not least because of the great demand for this technology on the Russian market," explains Stefan Karguth, Project Manager Machine Procurement at Robert BOSCH GmbH. The engineer designed and accompanied the project from Germany from the very beginning.

The plasma cutting system plays a key role in the production process. It is located directly next to the sheet metal storage and is loaded by a crane using a magnetic cross beam. Since the machine is therefore right at the beginning of the production chain, it is the most important link, according to Karguth: "When the plasma cutting system is at a standstill, all the following systems run empty. Accordingly, the requirements that BOSCH made when selecting new suppliers for the production line were stringent: In addition to an obligatory liquidity check, suppliers must, for example, have a certain size of operation, references are checked and it is checked whether in principle the ability to work according to the so-called BOSCH standards is given. MicroStep was able to meet the criteria. "We were well looked after right from the start," says Karguth about the MicroStep project team's appearance, which he considers professional and fact-oriented.

The system of the MG series from MicroStep currently operates in a 2-shift operation and cuts steel sheets with a material thickness of 5 to 18 mm and dimensions of up to 3,000 mm x 12,000 mm. Rectangular components as well as larger round contours and small holes are cut from these sheets. In addition, the components are also prepared for welding seams. The machine has a working area of 15,000 x 3,500 mm and has the following special features:

Plasma rotator for weld edge preparation

A highlight of the cutting system is the new R5 plasma rotator from MicroStep, which applies precise chamfers and weld edge preparations of up to 50° to components. Endless-rotating as standard, the unit delivers a cutting quality and process reliability never seen before in plasma bevel cutting. No matter whether X, Y, K or variable bevel. A series of patented assistance systems – such as the automatic calibration unit (ACTG®), a precise height control (ATHC®) and the adaptive bevel angle compensation (ABC®) – ensure very high dimensional accuracy. A HiFocus 280i from the company Kjellberg-Finsterwalde serves as power source. The suction technology consists of a powerful TEKA filter system.

Moving power source for hand cuts

The plant is equipped with a hand plasma source Kjellberg CUTi70 with a 6 meter long hose package. To accommodate this device a specially designed holding console was mounted on the gantry. In addition, a power connection as well as a compressed air connection was integrated on the gantry so that the plasma source does not have to be moved in case of operation.

"Among other things, the accuracy and positioning speed of the cutting system convinced us. And at MicroStep we get good service and good quality at a reasonable price".

Stefan Karguth

Project Manager Machine Procurement | Robert BOSCH GmbH

Machine profile:

MG series (Russia)

- Working area 15,000 x 3,500 mm

- Plasma rotator for weld preparation up to 50° with auto-calibration feature (ACTG®)

MG series (Germany)

- Working area 24,000 x 5,000 mm

- Cutting of domes Ø 300 – 4,000 mm up to a height of

1,000 mm

1. Gantry

- Plasma rotator for weld preparation up to 50° with auto-calibration feature (ACTG®)

- Console for manual oxyfuel torch

2. Gantry

- Plasma rotator for weld preparation up to 50° with auto-calibration feature (ACTG®)

- 2D oxyfuel

- Console for manual oxyfuel torch

- 3D scanner + mScan technology for compensation of the production-related deviation of dome shape by adjusting

the generated cutting paths according to the true scanned shape of dome

CombiCut series (Germany)

- Working area 24,000 x 3,500 mm

- Plasma rotator for weld preparation up to 50° with auto-calibration feature (ACTG®)

- Automatic plate edge detection

Automatic plate edge detection

On the rotator support there is a laser sensor that enables automatic plate detection on the cutting table. The control software iMSNC® from MicroStep in combination with the laser sensor can either determine only the corner of the plate or the corner with the angle of the plate position or the corner with the angle of the plate position and the plate size. After determining the plates, the acquired data can be transferred to the control. This enables fast setup of the plate and thus more economical processing of the cutting tasks at hand.

"Among other things, we were convinced by the accuracy and positioning speed of the cutting system," says Stefan Karguth. But also the fact that MicroStep responded to specific requests was decisive. Karguth summarizes: "Good service and good quality at a reasonable price."

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization