PL Compact

The ideal entry into

high-quality plasma cutting

PL Compact | The ideal entry level

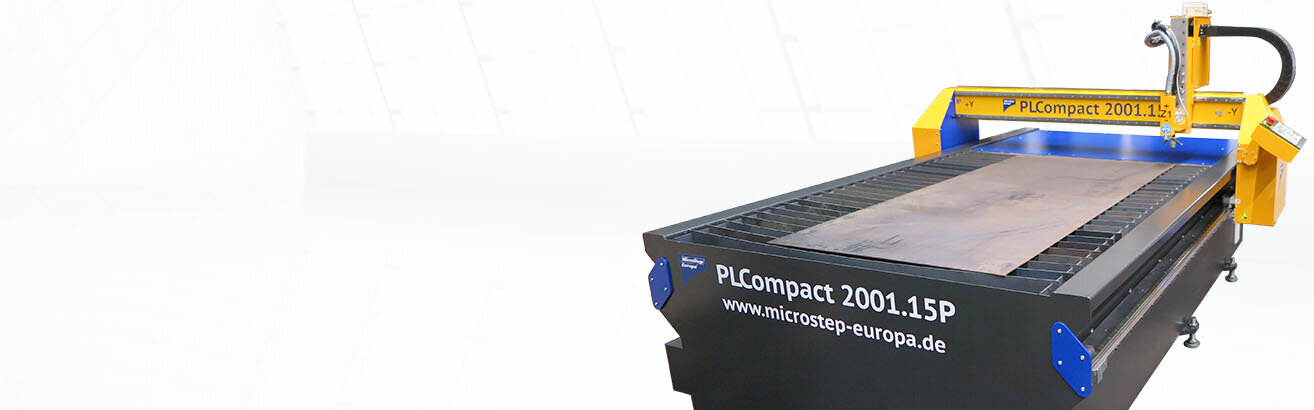

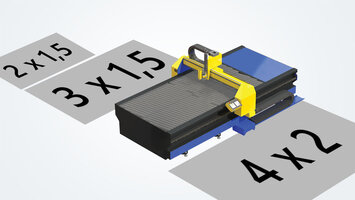

For getting started with CNC-controlled plasma cutting and performing simple cutting tasks, the PL Compact is the ideal machine. The series convinces with a compact and space-saving design as well as an excellent price-performance ratio. The PL Compact is available in four different processing areas – from 2,000 x 1,500 mm to 4,000 x 2,000 mm – and is designed especially for plasma cutting and marking. The use of high-quality components and the drive system synchronized on both sides ensure high and permanently reproducible precision of the entire guiding system.

These customers rely on MicroStep and benefit from the PL Compact

"Everything is really top-notch. The system runs reliably and well."

Prof. Dr.-Ing. Ralf Förster,

Vice Dean at Department VIII, Head of Laboratory for Production Engineering | Beuth University of Applied Sciences Berlin

Features

Adaptable: in 3 selectable system formats

To adapt the PL Compact to your production demands in the best possible way, we offer you the possibility to choose between...

Compact design and low space requirement

Space is precious – which is why the PL Compact was also designed as a complete stand-alone solution. Less space required for...

Installed and ready for operation within a short time

Thanks to the easySetup® installation concept, the system is assembled and ready for operation in a short time. A special...

High cutting quality, less post-processing

Better cutting quality means less post-processing – components can be further processed with significantly less effort, which...

Modern plasma systems: Cost-saving operation and maintenance

Cost savings are key – in comparison with laser systems, modern plasma cutting machines impress with their high cutting...

Training & expert support: Guarantee for high machine availability

To get the maximum efficiency out of your cutting system, perfectly trained operating personnel is essential. They ensure...

Technical specifications

Dimensions |

|||

| Effective length of work area | 2,000, 3,000, 4,000 mm | ||

| Effective width of work area | 1,500, 2,000 mm | ||

Tools |

|||

| Possible number of tools | 1 | ||

| Possible cutting processes | plasma | ||

| Maximum material thickness plasma | according to plasma source (max. 150 A) | ||

Precision |

|||

| Positioning speed | up to 30,000 mm/min. | ||

| Positioning accuracy | according to DIN 28206 / ≤ 0.15 mm/m | ||

| X, Y axis |

|

||

| Z axis | helical toothed racks | ||

| Gantry type | massive steel gantry | ||

Control & software |

|||

| Control | iMSNC® | ||

| Main control panel | ergonomic 17" touchscreen control panel | ||

| Operating system | Windows 11 Pro (64-bit) | ||

| Additional operating units | operating unit on the right or on the left side of the gantry | ||

| All specifications subject to change | |||

Software

Asper Basic

Asper Basic is the ideal tool for an easy and fast creation of NC programs for different cutting technologies (plasma, oxyfuel, laser or waterjet).

Control

MicroStep CyberFab® machine control

The intelligent solution for multi-technology work

CyberFab® from MicroStep is one of the most advanced control systems for CNC cutting machines. It was developed to easily, reliably, and efficiently turn cutting plans into finished parts with the help of a clear and modern user interface. The system’s hardware consists of a stand-alone control console with a TFT touchscreen and a control panel with an LCD display mounted on the gantry. In order to achieve maximum utilization and flexibility of our machines, the ergonomic control console offers the opportunity to nest new cutting programs and generate new CNC codes during an ongoing cutting process. As the CyberFab® control system and all CAM software solutions come from our company, the software with its versatile modules can be individually customized for your production. Parameter databases for individual technologies enable consistently high quality under various circumstances. CyberFab® comes with multiple efficient evaluation tools for production process optimization. These provide you with the much-needed overview of current cutting orders, cutting times, cost calculations and machine utilization in day-to-day production.

Overview of important performance data:

- 24’’ touchscreen

- Efficient management of tool data

- Very short programming times

- Fast data transfer

- Flexible and easy to use

- Advanced cutting simulation for more work safety

- Convenient contextual help via pop-up bubbles

Media

Cutting system

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

MSE TubeFL

MSE TubeFL

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization