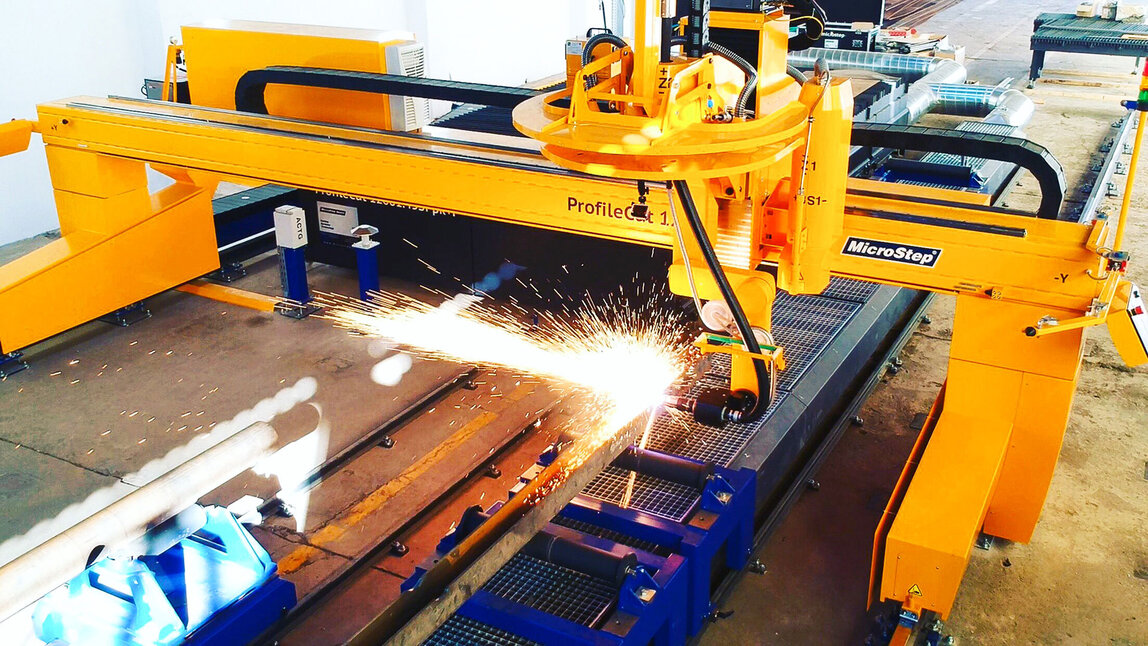

Bevel cutting of profiles, pipes and sheet metal: the flexible beam cutting machine ProfileCut with rotator "Pantograph"

Faster and better quality with new flexible cutting centre

The Spanish mechanical engineering company Innergy Heavy Industries relies on a multifunctional solution for 3D processing of beams, pipes and sheet metal

Published 23.11.2018 | Melanie Lingemann

Company profile:

Avda. Juan Ramón Jiménez, 646930 Quart de PobletSpain

INNERGY is a multinational company specializing in eco-friendly energy solutions. It consists of three divisions (Innergy

Heavy Industries, Innergy Electric and Innergy Engineering), has three international headquarters (Spain, Chile and Japan)

and has worked on more than 6,500 projects on 5 continents so far. At the Heavy Industries factory, the company produces

everything from industrial burner boilers and biomass boilers to complete power generation plants.

Machine profile:

ProfileCut series- Working area for sheets 12,000 x 4,500 mm

- Cutting of H, I, U beams up to HEB 1000 and a length of

12,000 mm - Cutting of pipes Ø 30 – 700 mm and hollow sections up to a

length of 12,000 mm - 3D plasma rotator "pantograph" with tilting up to 120° for weld

preparation on beams, pipes and plates + auto-calibration

feature (ACTG®)

INNERGY is a multinational company specializing in eco-friendly energy solutions thinking not only about the needs of the customer, but also about the needs of our planet. When it was founded 50 years ago, the company has specialized in design and manufacture of thermal oil boilers. However, over the time the world has changed and Innergy had to change with it. Today, its portfolio contains biomass generation and cogeneration plants, boilers or systems for use of residual heat.

Today the company has three separate divisions (Innergy Heavy Industries, Innergy Electric and Innergy Engineering), three international headquarters (Spain, Chile and Japan) and has worked on more than 6,500 projects on 5

continents.

Innergy opted for the ProfileCut from MicroStep with a working area of 12 x 4.5 meters for cutting of flat metal sheets. The machine is equipped with a pipe positioner and supporting rollers for cutting of pipes with a diameter up to 700 mm and profile cutting zone for cutting of H, U and L profiles up to 12 m long and 600 mm wide. The "pantograph" rotator is capable of tilting up to +/- 90° which makes the profile cutting feasible. All this supported by the XPR300® plasma source from Hypertherm. Mr. David Moldes, Chief Strategy and Corporate Development Officer, shared the decision making insights in a short interview:

Since 2017 you use a sheet and pipe cutting machine. Why did you decide for the ProfileCut from MicroStep?

David Moldes: “Acquisition of new equipment in Innergy follows strict rules since we need equipment which meets high quality standards characteristic for our company. We aim to continue providing our customers with state-of-the-art industrial boilers and other products and with this in mind, we decided for MicroStep's ProfileCut. During the selection process we didn’t only take the machine’s features into account. The important factor was also the good references MicroStep has on the market.”

How has the machine helped your manufacturing process?

David Moldes: “Having the machine has helped us mainly in two areas. First of all, by reducing manufacturing times and at the same time by improving the quality of our heater products. In addition, thanks to the incorporation of the ProfileCut we no longer have to outsource the parts cutting. That gives us both speed and self-sufficiency.”

The Innergy company relies on the ProfileCut series - thanks to the plasma rotator "pantograph" with its tilting capability of ±90° (120° on one side), beams can be processed circumferentially. In addition, the plasma cutting machine enables the processing of pipes and sheet metal.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization