CNC system solutions for your daily requirements

No matter what your requirements are for a CNC cutting system – MicroStep offers you the entire range of all relevant cutting

technologies (plasma, laser, oxyfuel and waterjet) – both in 2D and 3D. In addition, the systems can be individually adapted to

your production requirements with numerous options and connected to systems for automated material handling.

In addition, MicroStep also offers efficient solutions for the performance of your tasks regarding chip-forming machining, milling and bending.

MicroStep cutting solutions therefore help you to make your production even more efficient – day after day.

MSE SmartFL

The MSE SmartFL fiber laser cutting machine from MicroStep Europa and our technology partner ACCURL is a powerful as well as affordable system for high-quality 2D laser cutting. The series is available in cutting areas from 1,500 x 3,000 up to 2,500 x 12,000 mm and can be equipped with laser sources of up to 60 kW.

MSE SmartFL

MSE SmartFL

MSE CubeFL

The MSE CubeFL fiber laser cutting system from MicroStep Europa and our technology partner ACCURL is the ideal solution for compact laser cutting. It combines efficiency with minimal space requirements and enables the production of high-precision parts. The series is available in working areas from 1,000 x 2,000 to 1,500 x 3,000 mm and can be equipped with laser sources with an output of up to 12 kW.

MSE CubeFL

MSE CubeFL

MSE TubeFL

The MSE TubeFL fiber laser cutting system from MicroStep Europa and our technology partner ACCURL is a reliable system for high-quality and fast 2D and 3D laser cutting of pipes, profiles and beams. Depending on the version, an extremely high degree of automation and an output of up to 12 kW is possible. This means that the finest contours and openings as well as precise bevel cuts can be realized.

MSE TubeFL

MSE TubeFL

MSF Cut

The reliable fiber laser cutting machine for high-precision 2D cutting applications is available in three system formats with laser sources up to 15 kW – including an automatic shuttle table system as standard. The MSF Cut is a powerful production assistant to fulfill all standard tasks of fiber laser technology in a highly productive and high-quality configuration. Optionally, the laser cutting system can be further automated by MicroStep's material handling systems MSLoad, MSSort and MSTower.

MSF Cut

MSF Cut

MSF Pipe

A real expert for pipes and profiles: MicroStep has developed the MSF Pipe for the process-reliable, high-precision and fast 2D and 3D processing of pipes and profiles using fiber lasers. The system has an extremely high degree of automation. The loading and unloading as well as the sorting of cut parts can also be automated.

MSF Pipe

MSF Pipe

MSF Pipe

A real expert for pipes and profiles: MicroStep has developed the MSF Pipe for the process-reliable, high-precision and fast 2D and 3D processing of pipes and profiles using fiber lasers. The system has an extremely high degree of automation. The loading and unloading as well as the sorting of cut parts can also be automated.

MSF Pipe

MSF Pipe

MSF Compact

The MSF Compact combines precise 2D laser cutting with compact design. The series is available in work areas from 1,000 x 2,000 mm to 1,500 x 3,000 mm and impresses above all with its small footprint and the usual high cutting quality. A manually extractable cutting table allows easy and uncomplicated loading and unloading.

MSF Compact

MSF Compact

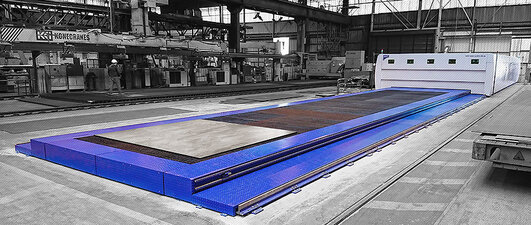

MSF Max

The MSF Max is the giant among fiber laser cutting solutions. Developed for processing large-format sheet metal for shipbuilding, it enables precise high-speed 3D processing of flat material. Thanks to the moving safety cabin, a work area size of up to 50 m length and 6 m width is available.

MSF Max

MSF Max

MSLoad, MSTower, MSSort

Solutions for loading, unloading and storage of sheets or sorting of cut parts: With the MicroStep technologies MSLoad, MSTower, MSSort you automate your cutting systems and get the absolute maximum out of it.

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

MSF Pipe

MSF Pipe

MSE TubeFL

MSE TubeFL

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization