The new one from MicroStep Europa: a laser for precise 2D cutting tasks

New laser series: entry into high-quality 2D laser cutting

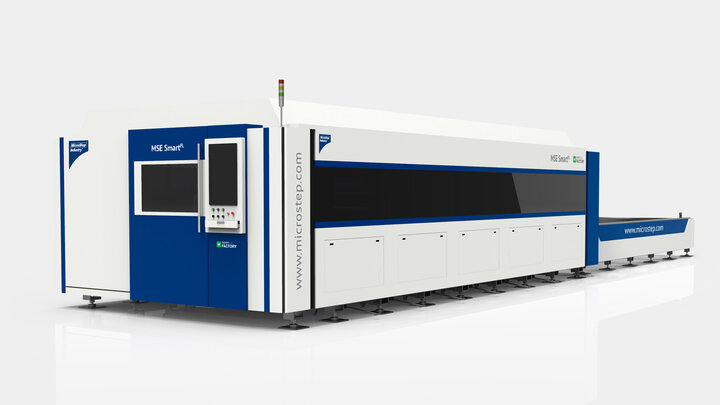

With the MSE SmartFL fiber laser cutting system, MicroStep Europa is launching a high-performance system in the market. For customers looking for quality at manageable investment costs.

Published 20.04.2021 | Erich Wörishofer

Raise the curtain on the MSE SmartFL: MicroStep Europa presents a new laser series. A series developed to provide a powerful entry into high-quality 2D laser cutting. Reliable and process-safe thanks to high-quality brand components, easy and smart to control due to MicroStep's AsperWin® Basic software and the MSE SmartControl control system. The series is also ready for the digitalized production of tomorrow.

MicroStep's laser portfolio is extensive, ranging from compact systems and specialists to multifunctional and highly automated all-rounders for 3D processing of sheet metal, pipes and profiles. Now MicroStep Europa presents a series that has been developed to offer top quality for customers – and at manageable investment costs: the MSE SmartFL is a powerful entry-level machine for high-quality 2D laser cutting. A cast aluminum gantry has been integrated, the highly rigid and weight-optimized design enables high accelerations. The fiber laser system, which is equipped with an automatic shuttle table as standard, is available in working areas from 1,500 x 3,000 to 2,500 x 6,000 mm and can be provided with laser sources of up to 12 kW. "With the MSE SmartFL series, we are completing our portfolio. The fiber laser offers top quality at an entry-level price and this, of course, combined with our usual top service," explains Johannes Ried, Managing Director of MicroStep Europa GmbH.

Fiber laser cutting 4.0: With the MSE SmartFL series, MicroStep Europa GmbH is launching a 2D laser cutting system that offers top quality at manageable investment costs. Powerful, reliable and economical with high-quality components throughout. And equipped for the connected production of tomorrow.

Components „Made in Germany“

The machine owes its high reliability and process safety to the fact that it is equipped throughout with extremely high-quality brand-name components. "Made in Germany" applies to the entire list of components: The new MSE SmartFL is equipped with the German-made EX-TRABEAM® PRO Thermacut cutting head with low-drift control for the best cutting results, as well as the "Smart Protection" seal monitoring system to protect the optical components. The laser source also comes from Germany: MicroStep Europa relies here on the innovative products of IPG Photonics. The energy-saving shuttle table with sectional suction is extracted by another new series: the AirCube, from Teka. The MSE SmartControl, developed jointly with Eckelmann, is integrated as the control system, and users can rely on AsperWin® Basic from MicroStep for the 2D CAM software. Also integrated are servo drives from Eckelmann, gears and racks from Wittenstein alpha, and linear guides from Bosch Rexroth.

Ready for Industry 4.0

With the new series, users are also optimally equipped for future requirements of digital production. Because the MSE SmartFL is prepared for the use of IndustryFusion, a manufacturer-independent open source networking solution for smart factories and smart products. The networking solution, developed by medium-sized mechanical engineering companies in the Industry Business Network 4.0 association and the IndustryFusion Foundation together with corporations such as Intel, TÜV Süd as well as research institutions such as the Fraunhofer IGCV, offers complete transparency over all connected systems and machines in your production – and thus enables even more efficient and automated production.

"With the MSE SmartFL series, we complete our portfolio. The fiber laser offers top quality at an entry-level price and this, of course, combined with our usual top service".

Johannes Ried

Managing Director| MicroStep Europa GmbH

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization