Processing options

A special machine for each task? This maxim has long been a thing of the past in the metalworking industry. In order to be able to meet the increasing demands of existing and potential customers efficiently and with high quality in the future, companies in the industry are increasingly relying on multifunctional machine solutions in addition to automation. This saves time and space in production and also creates the urgently needed flexibility to adapt to constantly changing customer requirements at short notice. There is a wide range of potential processing options that can be combined on a CNC machine in order to produce more efficiently, flexibly and even more economically – down to the smallest batch sizes.

Pipe & profile processing

Pipes and profiles up to 1,000 mm in diameter can be processed using pure tube cutting systems or combined flatbed tube systems (plasma, oxyfuel, laser, waterjet).

Find out more

Dome processing

With pure dome cutting machine or combined solutions, contours and chamfers can be cut in domes up to 10,000 mm in diameter.

Find out more

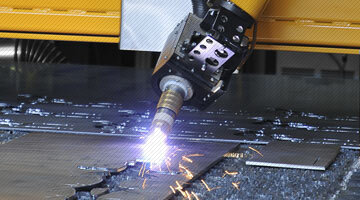

2D cutting

Using plasma, oxyfuel, laser or water jet technology, contours and holes of any size can be cut from sheet metal, tubes or profiles.

Find out more

Bevel cutting (weld edge preparation)

Laser, plasma, oxyfuel and waterjet technology can be used to cut bevels on sheets, pipes and profiles, for example for weld edge preparation.

Find out more

Drilling, tapping, countersinking

By equipping a CNC cutting system with technologies for drilling, tapping and countersinking, the flexibility and efficiency of production can be increased.

Find out more

Marking

Plasma, needle, inkjet or pure water can be used to mark, label and, in some cases, grain workpieces (sheet metal, pipes, profiles, container bases).

Find out more

Scanning

The scanning of workpieces is used, among other things, for the exact and precise further processing of sheet metal, pipes, profiles and domes.

Find out more

Automation

Industry 4.0 in practice: Production can be made more efficient with intelligent automation solutions for work and set-up processes.

Find out more

ABP – Additional Beveling Process

Efficient alternative to robots: ABP® technology (Additional Beveling Process) enables extremely precise subsequent beveling on portal cutting systems.

Find out more

Multifunctionality

Whether 2D cutting, 3D cutting, drilling, tapping, countersinking and marking – cutting systems allow multifunctional processing of sheet metal, pipes, profiles and domes

Find out more

Safety

The safety of operating personnel is a key aspect in the planning of industrial production processes - this requires a customized safety concept.

Find out more SMART Cube X

SMART Cube X

SmartLINE X

SmartLINE X

MasterLINE X

MasterLINE X

SMART Giant X

SMART Giant X

TubeLINE

TubeLINE

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

SMART

SMART

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

GENIUS

GENIUS

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization